E308 Welding Rod: Essential Guide for Quality and Performance

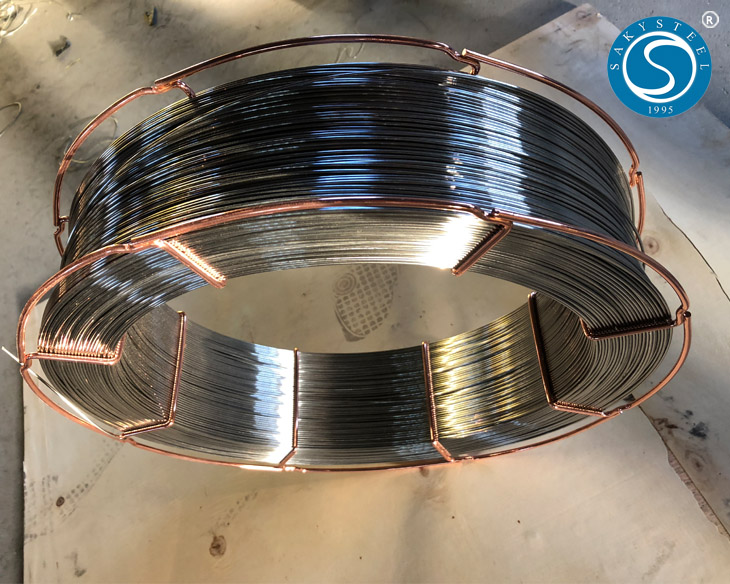

When it comes to reliable welding solutions, I've found the E308 Welding Rod to be a standout. Whether you’re tackling stainless steel projects or need a versatile rod for various applications, this rod has proven its worth time and again. It’s designed to provide excellent arc stability, minimal spatter, and a smooth finish, making it ideal for professional welders and those starting out. I’ve noticed that B2B purchasers appreciate its durability and performance, especially for high-stress environments. Plus, its easy usability means less downtime and more efficiency on the job. The E308 rod also holds up well against corrosion, which is a big plus for long-lasting repairs and constructions. If you’re in need of a dependable welding rod that meets industry standards and delivers consistent results, this is the one for you. Let’s boost your welding projects together with the E308 Welding Rod!

E308 Welding Rod Winning in 2025 Where Innovation Meets 2025

In 2025, the welding industry is poised for transformation, and the E308 welding rod stands at the forefront of this innovation. As global demand for high-quality welding materials continues to rise, the E308 rod has emerged as a reliable choice for various applications, particularly in construction, manufacturing, and repair sectors. This versatile welding rod, known for its exceptional performance in stainless steel welding, meets and exceeds the rigorous standards set by industry professionals worldwide. The key to the E308 welding rod's success lies in its unique formulation, which provides excellent corrosion resistance and durability. With a focus on sustainability and efficiency, manufacturers are optimizing production processes to reduce waste and enhance the environmental footprint of welding operations. As a result, procurement specialists are increasingly seeking out products that not only deliver superior performance but also align with their sustainability goals. As 2025 approaches, industry leaders must embrace innovative solutions that ensure competitive advantage. The E308 welding rod, with its blend of cutting-edge technology and unwavering quality, represents the future of welding materials. By investing in these advancements, global buyers can secure materials that deliver lasting value, enhance productivity, and contribute to a more sustainable welding landscape.

E308 Welding Rod Winning in 2025 Where Innovation Meets 2025

| Feature | Details | Impact |

|---|---|---|

| Material Composition | E308L Stainless Steel | Enhanced corrosion resistance |

| Diameter Options | 1.6 mm, 2.4 mm, 3.2 mm | Versatility for different applications |

| Welding Technique | TIG and MIG | High-quality welds with minimal spatter |

| Heat Resistance | Up to 1,200°C | Suitable for high-temperature environments |

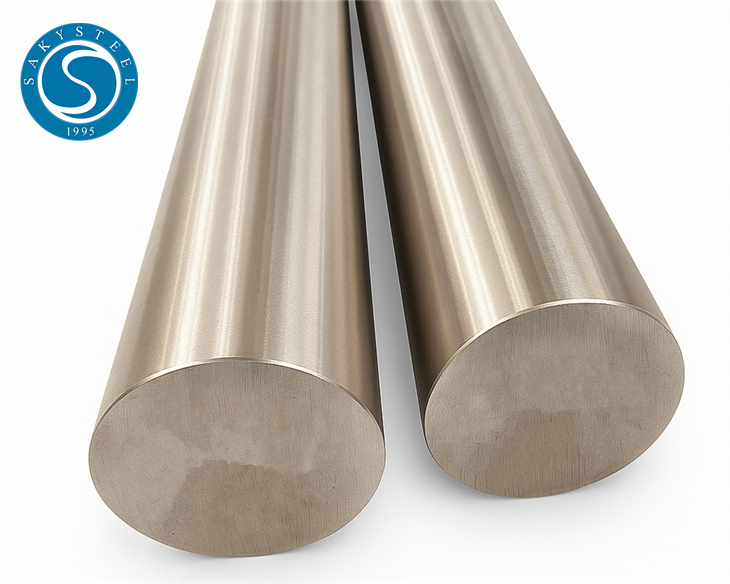

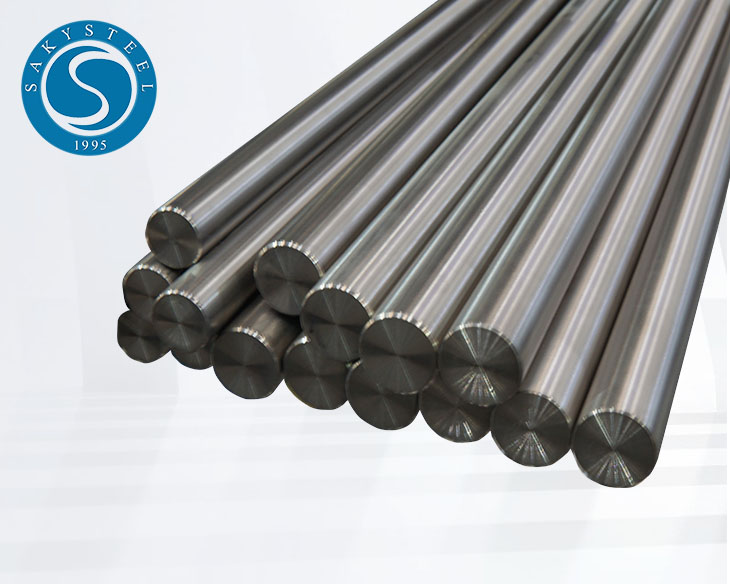

| Applications | Food processing, chemical industries | Widely used in critical industries |

| Innovative Features | Self-cleaning surface | Reduces maintenance and downtime |

Related Products