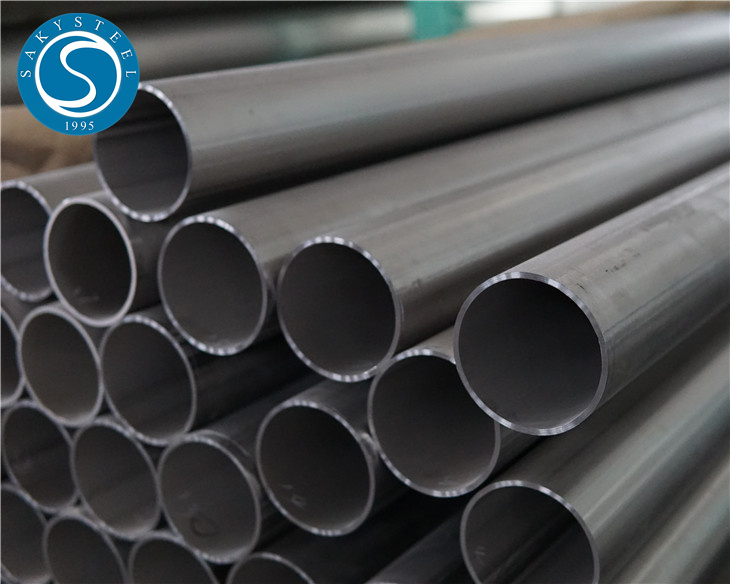

High-Quality Stainless Steel 304L Tubes for Industrial Applications

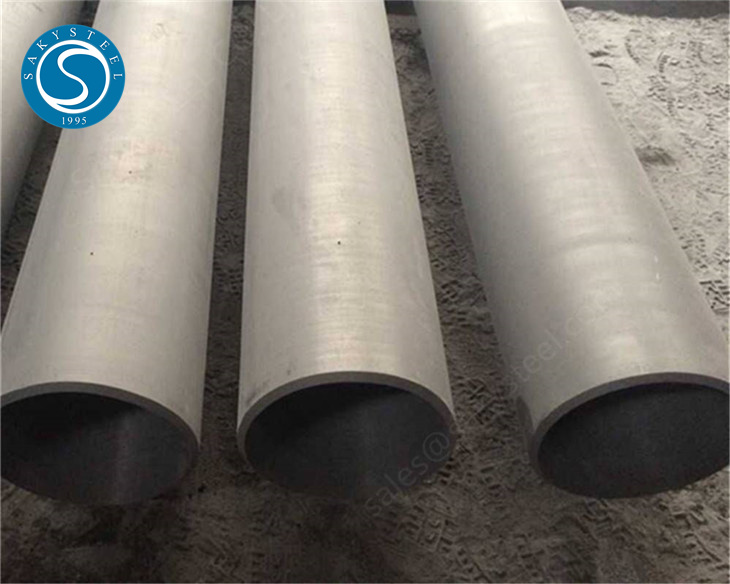

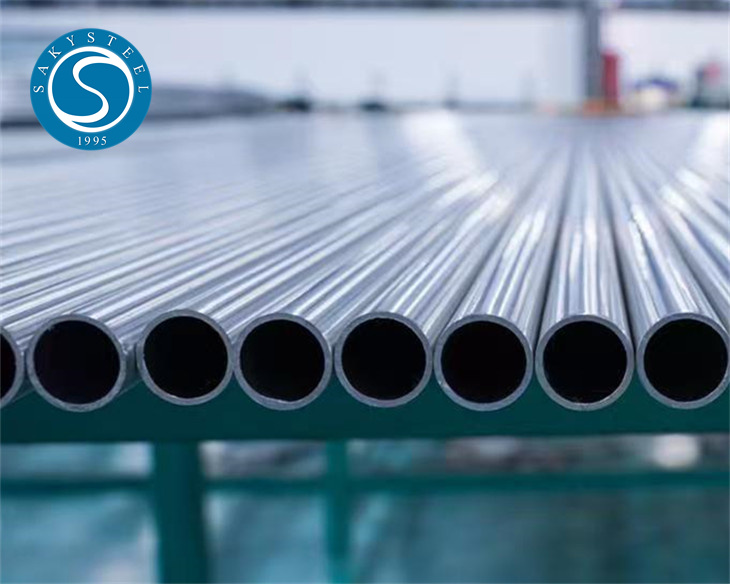

When it comes to high-performance materials, I find myself always recommending Stainless Steel 304L Tubes. These tubes offer exceptional corrosion resistance and excellent weldability, making them ideal for a wide range of applications, from construction to manufacturing. I've seen firsthand how businesses benefit from using these tubes because they are durable and reliable, even in harsh environments. With their low carbon content, these 304L tubes minimize carbide precipitation, ensuring that structural integrity remains intact. If your projects demand longevity and strength, you won't go wrong here. With various sizes and specifications available, it’s easy to find the perfect fit for your specific needs. I can help you source these tubes quickly and reliably, so don't hesitate to reach out if you want to explore options or need assistance with bulk orders. Knowing you have the best materials at your disposal can truly make a difference in your operations!

Stainless Steel 304l Tubes Manufacturer Where Service Meets Innovation

In today's competitive market, finding a reliable stainless steel tube manufacturer can be challenging, particularly for global buyers seeking quality and innovation. When it comes to sourcing Stainless Steel 304L tubes, it's essential to partner with a manufacturer that not only excels in superior product offerings but also prioritizes exceptional customer service. This unique blend of quality and service is what sets the best manufacturers apart, ensuring that clients receive not only the best products but also the best overall purchasing experience. The demand for Stainless Steel 304L tubes is growing due to their excellent corrosion resistance and versatility in various applications, including construction, automotive, and marine industries. As buyers seek to invest in durable and high-performance materials, choosing a manufacturer that leverages advanced technology and innovative practices becomes crucial. By focusing on continuous improvement and fostering relationships with clients, leading manufacturers can offer tailored solutions that meet the specific needs of different projects while maintaining high international standards. Moreover, a strong commitment to sustainability and ethical practices further enhances a manufacturer's appeal in the global marketplace. Buyers are increasingly aware of their impact on the environment, making it important to align with suppliers who prioritize eco-friendly processes and materials. By fostering transparency and accountability, top manufacturers not only meet but exceed the expectations of discerning buyers, paving the way for successful long-term partnerships built on trust and mutual benefit.

Stainless Steel 304l Tubes Manufacturer Where Service Meets Innovation

| Specification | Application | Standard | Finish | Diameter (mm) | Length (m) |

|---|---|---|---|---|---|

| SS304L Tube 20x3 | Oil & Gas | ASTM A312 | Polished | 20 | 6 |

| SS304L Tube 25x5 | Chemical Processing | ASTM A249 | Brushed | 25 | 6 |

| SS304L Tube 32x4 | Food & Beverage | ASTM A270 | Pickled | 32 | 6 |

| SS304L Tube 50x7 | Construction | EN 10216-5 | Electropolished | 50 | 6 |

Related Products