Top Stainless Steel Tig Filler Rods for Quality Welding Projects

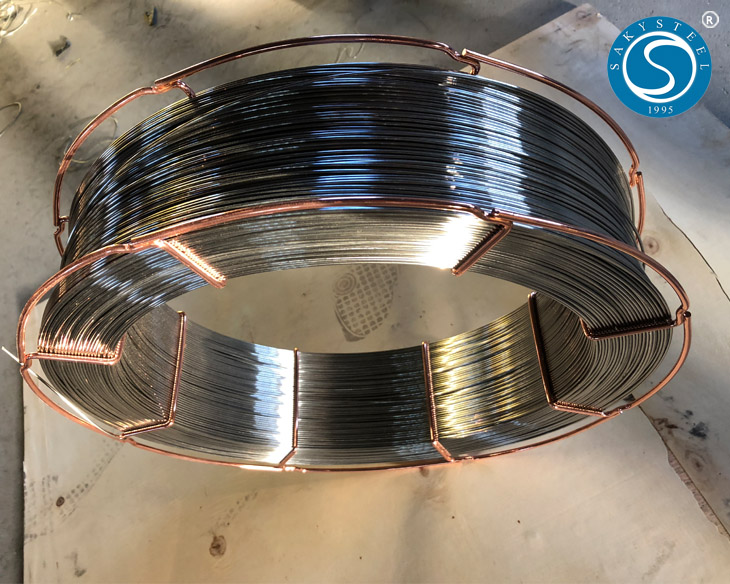

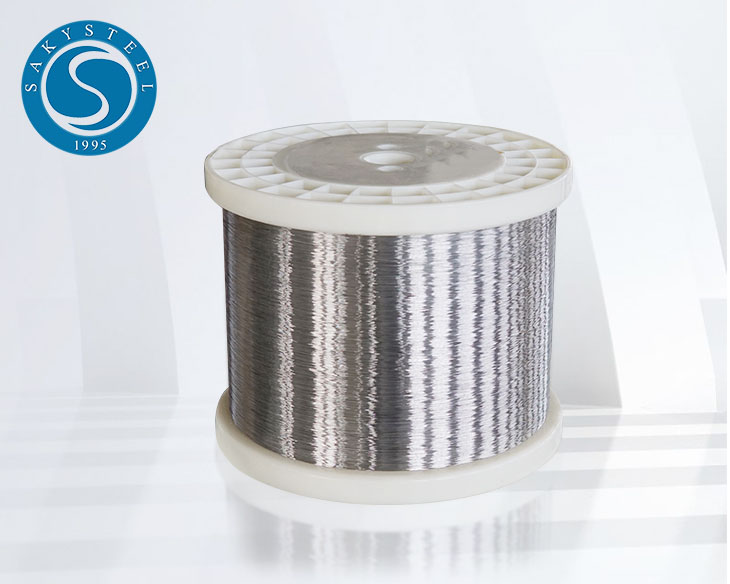

When I first tried the Stainless Steel Tig Filler Rod, I was impressed by its quality and performance. It’s perfect for welding projects that require strength and durability. Whether you’re in manufacturing or construction, this rod is a game-changer for joining stainless steel. The rod provides excellent corrosion resistance and smooth feeding, which saves time and enhances your workflow. With features designed for both beginners and seasoned professionals, it’s easy to see why many B2B purchasers are choosing it. I often find it outperforms competitors in terms of ease of use and strength. Plus, the ability to handle high heat makes it a reliable choice for diverse applications. This product has truly elevated my projects. If you value reliability and performance in your welding materials, give the Stainless Steel Tig Filler Rod a try – you won’t be disappointed!

Stainless Steel Tig Filler Rod Industry Giant Ahead of the Curve

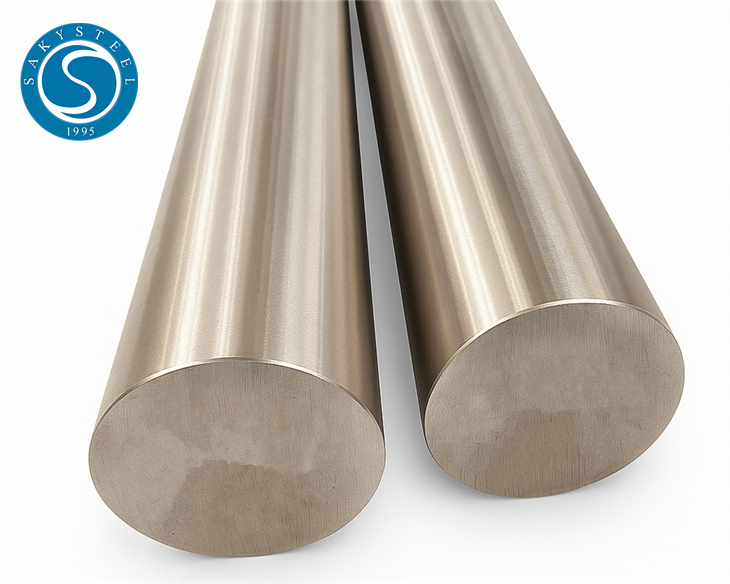

In the ever-evolving landscape of the stainless steel TIG filler rod industry, staying ahead of the curve is essential for meeting global demand and enhancing operational efficiency. As businesses navigate the challenges of fluctuating material costs and evolving technology, companies that leverage innovation and sustainable practices are poised to lead the market. The focus on high-quality filler rods that ensure superior weld strength and enhanced corrosion resistance is no longer a luxury but a necessity for industries ranging from automotive to aerospace. The key to success lies in adopting advanced manufacturing techniques and maintaining stringent quality control throughout the production process. Emphasizing the importance of customized solutions tailored to meet specific client requirements can significantly enhance customer satisfaction and loyalty. With an increased emphasis on eco-friendly materials and processes, manufacturers are not only improving their sustainability footprint but also appealing to a broader range of environmentally-conscious buyers across the globe. As the demand for stainless steel products continues to rise, companies that prioritize innovation, quality, and sustainability will undoubtedly set themselves apart. Engaging with trusted suppliers who can deliver exceptional products consistently will enable global buyers to streamline their operations and secure a competitive edge in their respective markets. Embracing these principles will be vital for any organization looking to thrive in this dynamic industry.

Stainless Steel Tig Filler Rod Industry Giant Ahead of the Curve

| Dimension | Material | Type | Application | Welding Process | Strength (MPa) |

|---|---|---|---|---|---|

| 1.6 mm | Stainless Steel 304 | Filler Rod | Food Industry | TIG | 590 |

| 2.4 mm | Stainless Steel 316 | Filler Rod | Chemical Processing | TIG | 600 |

| 3.2 mm | Stainless Steel 308L | Filler Rod | Marine Applications | TIG | 580 |

| 4.0 mm | Stainless Steel 321 | Filler Rod | Aerospace | TIG | 620 |

Related Products