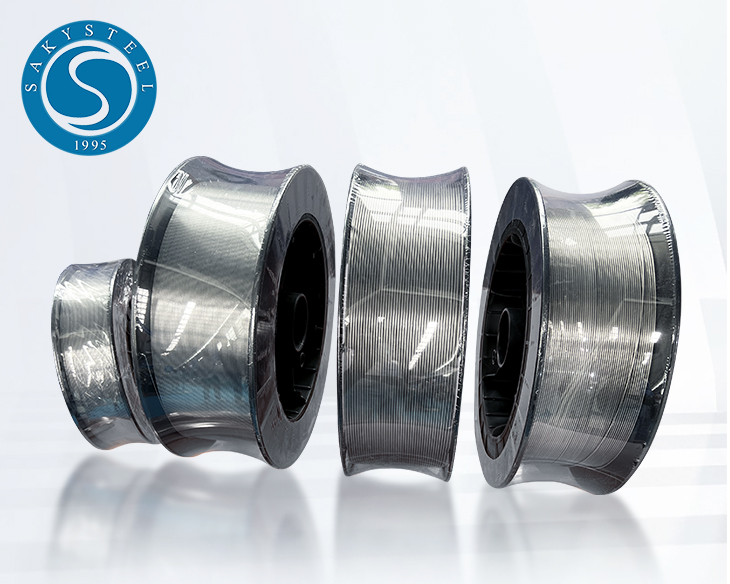

Top Stainless Steel Tig Welding Wire for Precision Welding Projects

When it comes to durability and performance, I trust Stainless Steel Tig Welding Wire for all my projects. This high-quality wire is perfect for creating strong and reliable welds, making it an essential choice for any professional welder. Its fantastic corrosion resistance and ability to maintain integrity at high temperatures are just what I need for both industrial and commercial applications. Whether you're fabricating metal structures or performing intricate repairs, this wire provides excellent feedability and a smooth arc. I love how versatile it is, suitable for various stainless steel grades, ensuring that I can tackle a wide range of tasks without worrying about compatibility. With competitive pricing and reliable availability, it's a smart choice for those looking to optimize their welding processes without sacrificing quality. Trust me, investing in the right welding wire can make all the difference in achieving flawless results. You won't regret trying out Stainless Steel Tig Welding Wire!

Stainless Steel Tig Welding Wire Manufacturer Market Leader

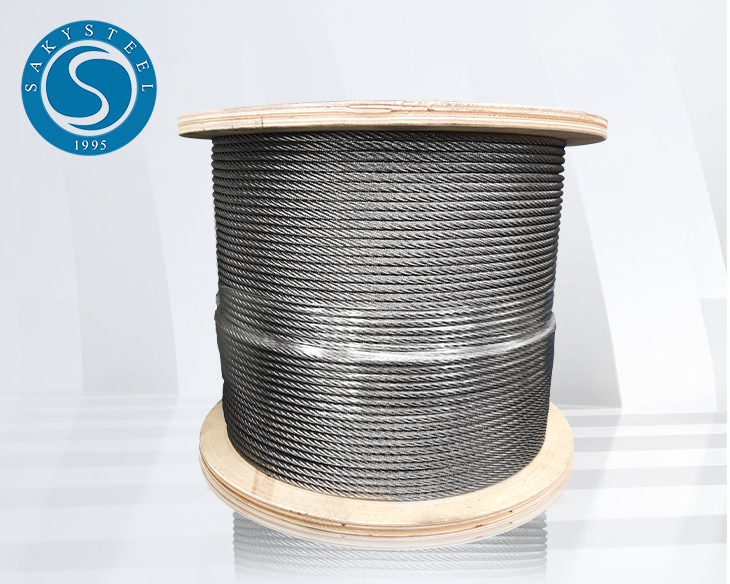

In the competitive landscape of metal fabrication, stainless steel TIG welding wire plays a critical role in ensuring the quality and strength of welded joints. Leading manufacturers have recognized the growing demand for high-performance materials that cater to diverse industries, from automotive to construction. By investing in advanced production techniques and rigorous quality control processes, these manufacturers are able to provide welding wires that meet international standards, offering reliability and excellence for professionals worldwide. The market for stainless steel TIG welding wire is witnessing significant growth as industries increasingly turn to stainless steel for its corrosion resistance and durability. Sourcing from a top-tier manufacturer ensures that global buyers receive products that not only enhance the welding process but also align with sustainability goals. With the ability to offer a wide range of specifications and customized solutions, these manufacturers help businesses optimize their welding operations while reducing costs. For procurement professionals, choosing the right welding wire supplier is crucial. Evaluating factors such as product quality, consistency, and technical support can make a substantial difference in project outcomes. By fostering strong partnerships with established manufacturers, buyers can gain access to innovative products and expert advice, ultimately driving productivity and success in their operations.

Stainless Steel Tig Welding Wire Manufacturer Market Leader

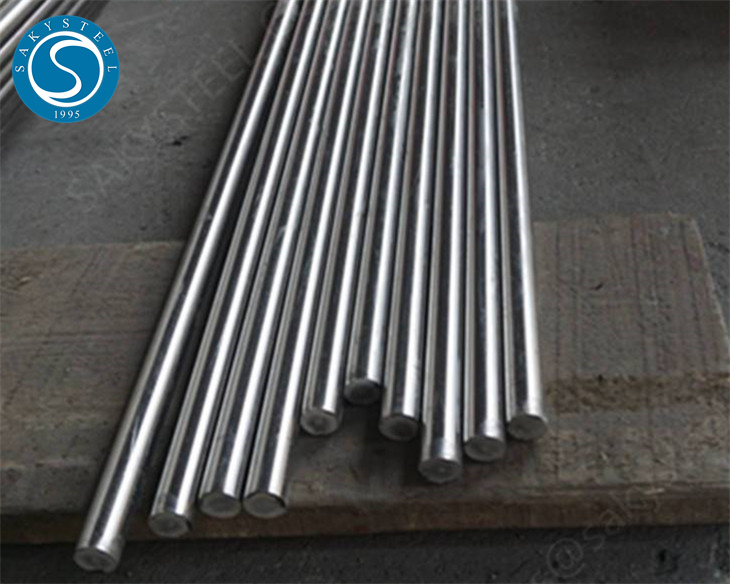

| Manufacturer | Country | Product Type | Diameter (mm) | Tensile Strength (MPa) | Applications |

|---|---|---|---|---|---|

| Manufacturer A | USA | ER308L | 1.0 | 520 | Food Industry |

| Manufacturer B | Germany | ER316L | 1.2 | 580 | Marine Applications |

| Manufacturer C | China | ER309L | 0.8 | 600 | Construction |

| Manufacturer D | Japan | ER347 | 1.0 | 500 | Automotive |

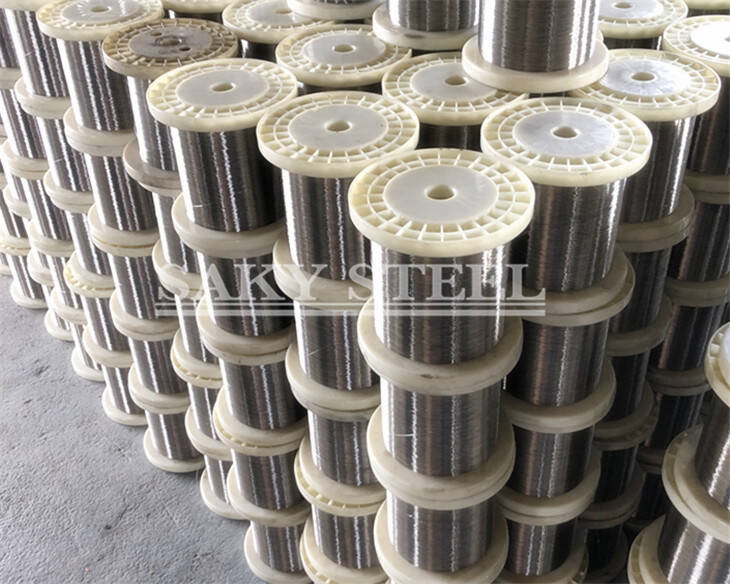

Related Products