304 Stainless Steel Tig Filler Rod for High-Quality Welding Projects

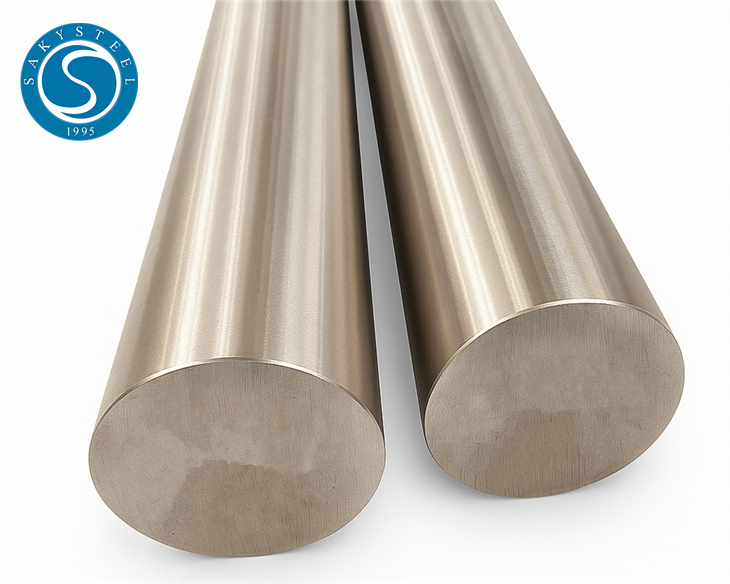

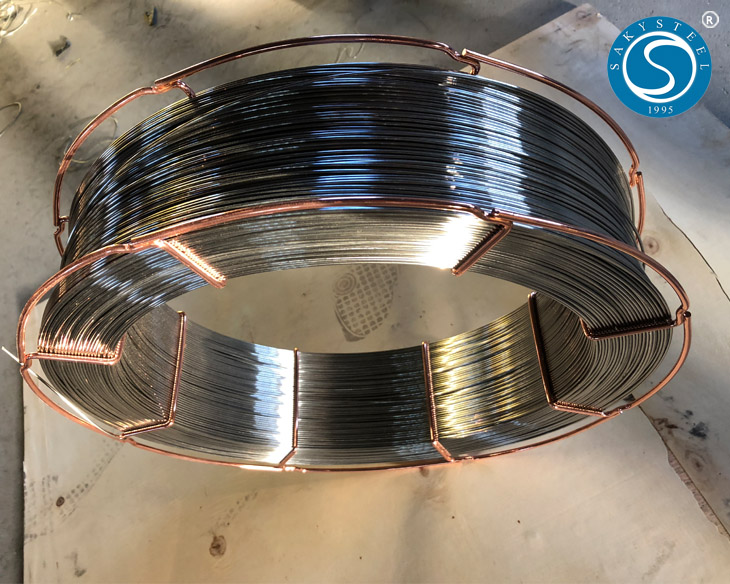

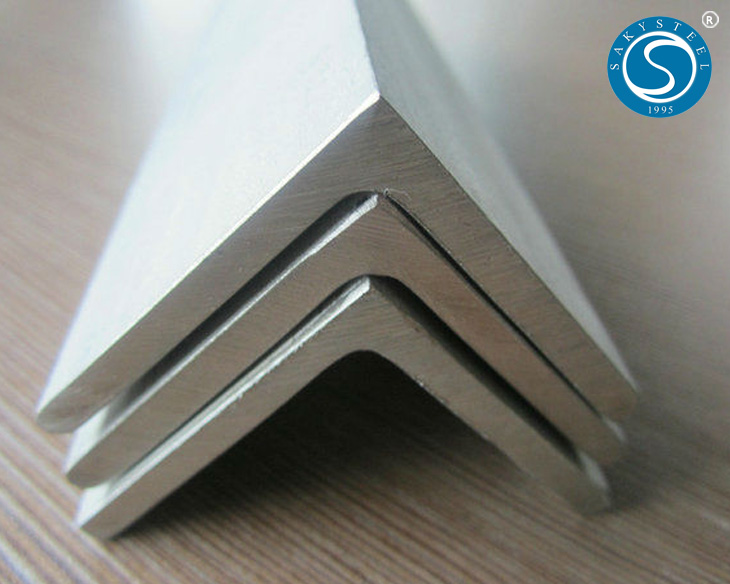

When I think about quality welding projects, 304 Stainless Steel Tig Filler Rod comes to mind. This filler rod, designed for the toughest applications, ensures strong and lasting welds in all your stainless steel work. Perfect for both professionals and enthusiasts, it offers excellent corrosion resistance, making it ideal for a variety of industries including food processing, chemical, and construction. I appreciate how easy it is to handle, allowing for precise control during the welding process. With various diameters available, it suits diverse project needs – whether you're fabricating or repairing equipment. Plus, its compatibility with standard TIG welding processes means integration into your workflow is seamless. Transitioning to this dependable filler rod not only boosts the durability of my welds but also enhances my overall efficiency. If you value quality and performance in your welding supplies, this is a great choice for your business.

304 Stainless Steel Tig Filler Rod Winning in 2025 Custom Solutions,

In the competitive landscape of industrial materials, 304 stainless steel TIG filler rods are emerging as essential components for various applications. As global demand continues to rise, especially in sectors such as construction, automotive, and aerospace, buyers are seeking reliable and innovative solutions to meet their specific needs in 2025 and beyond. The versatility of 304 stainless steel, known for its excellent corrosion resistance and strength, makes it a preferred choice among manufacturers who aim for durability and quality in their products. Custom solutions are becoming increasingly vital as procurement strategies evolve. Buyers are not just looking for standard products; they are looking for tailored materials that seamlessly integrate into their production processes. This shift towards customization allows companies to optimize performance while also adhering to stringent industry standards. By collaborating closely with suppliers who understand the intricacies of their requirements, businesses can benefit from enhanced efficiency and reduced waste, ultimately leading to cost savings and improved product outcomes. As we look to the future, investing in high-quality 304 stainless steel TIG filler rods and innovative custom solutions will be key. This not only ensures compliance with international standards but also positions companies to thrive in an ever-changing market. Embracing the latest technological advancements in manufacturing and forging strong partnerships will empower global buyers to stay ahead in their sectors, ensuring they meet the challenges of 2025 with confidence and resilience.

304 Stainless Steel Tig Filler Rod Winning in 2025 Custom Solutions

| Diameter (mm) | Length (mm) | Applications | Mechanical Properties |

|---|---|---|---|

| 1.6 | 1000 | Food Processing, Chemical Industry | Tensile Strength: 515 MPa |

| 2.4 | 1000 | Automotive, Aerospace | Tensile Strength: 525 MPa |

| 3.2 | 1000 | Construction, Shipbuilding | Tensile Strength: 540 MPa |

| 4.0 | 1000 | Pressure Vessel, Power Generation | Tensile Strength: 560 MPa |

Related Products