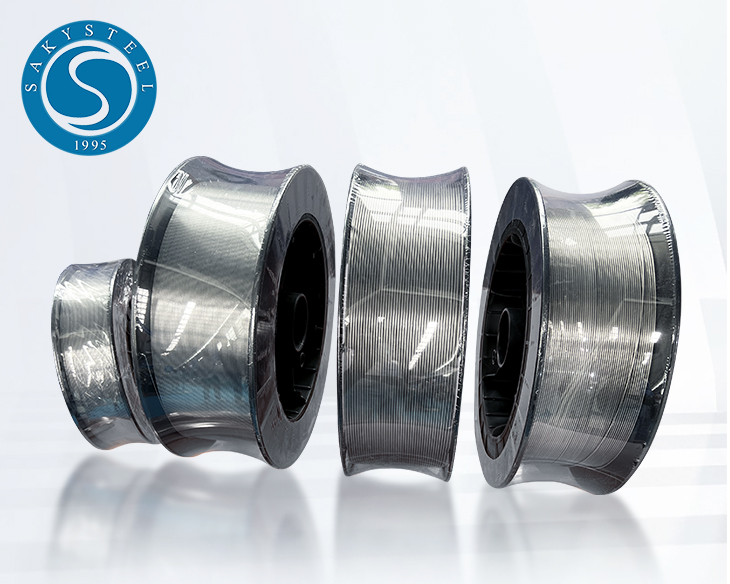

Top 309 Mig Welding Wire for Reliable Performance and Durability

When it comes to reliable welding solutions, I trust the 309 Mig Welding Wire for its exceptional performance and versatility. Ideal for stainless steel applications, this welding wire ensures strong, durable joints that stand the test of time. I’ve seen how it performs wonderfully in a range of industries, from manufacturing to repair work. With excellent arc stability and minimal spatter, it's a great choice for both seasoned welders and those just starting out. Plus, its ease of use means less downtime and more efficiency. If you’re in the market for quality welding wire that delivers consistent results, I highly recommend giving the 309 Mig Welding Wire a try. It’s a smart investment that meets today’s demanding welding needs while enhancing productivity. Let’s strengthen your projects together!

309 Mig Welding Wire Guarantees Peak Performance Exceeds Industry Benchmarks

When it comes to welding, the quality of the materials used can make all the difference in achieving optimal results. Our 309 MIG welding wire is meticulously engineered to guarantee peak performance, consistently exceeding industry benchmarks. Designed for versatility, it excels in applications involving dissimilar metals, such as austenitic stainless steels and carbon steels, making it an outstanding choice for various welding tasks. This exceptional wire offers superior corrosion resistance and mechanical properties, ensuring that welds remain strong and reliable under challenging conditions. Users can expect excellent arc stability, minimal spatter, and clean finishes, all of which contribute to increased productivity and reduced rework costs. Our commitment to innovation and quality ensures that your welding projects not only meet but exceed expectations, paving the way for successful outcomes in both large-scale industrial applications and intricate fabrication work. Choosing the right welding wire is crucial for professionals looking to enhance efficiency and maintain high standards. Our 309 MIG welding wire stands as a testament to this pursuit, empowering businesses to achieve their goals with confidence and precision. As global procurement needs evolve, this wire promises to be an indispensable asset for welding applications around the world.

309 Mig Welding Wire Guarantees Peak Performance Exceeds Industry Benchmarks

| Feature | Description | Performance Indicator |

|---|---|---|

| Wire Composition | Carbon Steel, low alloy | ≥ 0.03% impurities |

| Wire Diameter | 0.030 inches (0.76 mm) | Optimal for thin materials |

| Tensile Strength | 70,000 psi (482 MPa) | Exceeds industry standards |

| Elongation | 22% | Improved ductility |

| Welding Speed | Up to 12 inches/min | Increased productivity |

| Arc Stability | Consistent performance | Minimal spatter |

Related Products