With the rapid development of social economy, the vast ocean space and rich marine resources have begun to enter people's field of vision. The ocean is a huge resource treasure house, rich in biological resources, energy resources and ocean energy resources. The development and utilization of marine resources are inseparable from the research and development of marine special materials, and friction and wear in harsh marine environments are key issues that restrict the application of marine materials and the development of marine equipment. Study the corrosion and wear behavior of 316L and 2205 stainless steel under two commonly used seawater conditions: seawater corrosion wear and cathodic protection, and use a variety of testing methods such as XRD, metallography, electrochemical testing and corrosion and wear synergy to analyze the microstructure phase changes From the angle, the effect of seawater sliding wear on the corrosion and wear properties of stainless steel is analyzed.The research results are as follows:

(1) The wear rate of 316L under high load is smaller than the wear rate under low load. XRD and metallographic analysis show that 316L undergoes martensitic transformation during seawater sliding wear, and its transformation efficiency is about 60% or more; Comparing the martensite transformation rates under two seawater conditions, it was found that seawater corrosion hinders the martensite transformation.

(2) Potentiodynamic polarization scanning and electrochemical impedance methods were used to study the influence of 316L microstructural changes on corrosion behavior. The results showed that the martensitic phase transformation affected the characteristics and stability of the passive film on the surface of stainless steel, leading to the corrosion of stainless steel. The corrosion resistance is weakened; electrochemical impedance (EIS) analysis also reached a similar conclusion, and the generated martensite and untransformed austenite form microscopic electrical coupling, which in turn changes the electrochemical behavior of stainless steel.

(3) The material loss of 316L stainless steel under seawater includes pure friction and wear material loss (W0), the synergistic effect of corrosion on wear (S') and the synergistic effect of wear on corrosion (S'), while the martensitic phase transformation affects The relationship between the material loss of each part is explained.

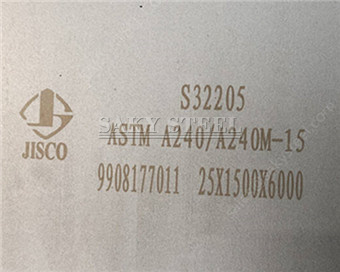

(4) The corrosion and wear behavior of 2205 dual-phase steel under two seawater conditions was studied. The results showed that: the wear rate of 2205 dual-phase steel under high load was smaller, and seawater sliding wear caused the σ phase to occur on the surface of the dual-phase steel. Microstructural changes such as deformations, dislocations and lattice shifts improve the wear resistance of dual-phase steel; compared with 316L, 2205 dual-phase steel has a smaller wear rate and better wear resistance.

(5) An electrochemical workstation was used to test the electrochemical properties of the wear surface of the dual-phase steel. After sliding wear in seawater, the self-corrosion potential of the 2205 dual-phase steel decreased and the current density increased; from the electrochemical impedance test method (EIS ) also concluded that the resistance value of the wear surface of duplex steel decreases and the seawater corrosion resistance is weakened; the σ phase produced by the sliding wear of duplex steel by seawater reduces the Cr and Mo elements around the ferrite and austenite , making duplex steel more susceptible to seawater corrosion, and pitting pits are also prone to form in these defective areas.

(6) The material loss of 2205 duplex steel mainly comes from pure friction and wear material loss, accounting for about 80% to 90% of the total loss. Compared with 316L stainless steel, the material loss of each part of duplex steel is greater than that of 316L. Small.

In summary, it can be concluded that 2205 dual-phase steel has better corrosion resistance in seawater environment and is more suitable for application in seawater corrosion and wear environment.

Post time: Dec-04-2023