309 Tig Rod for Precision Welding: Durable, Versatile & High-Quality

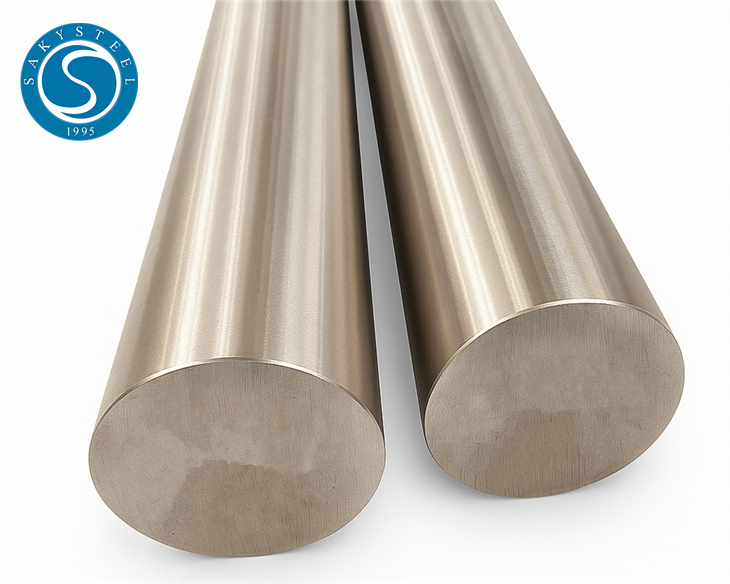

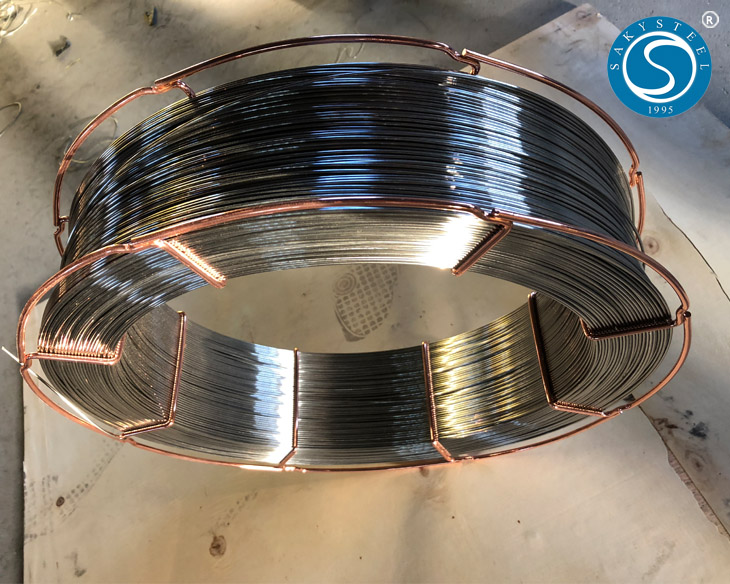

When I first found the 309 Tig Rod, I knew instantly it was the perfect choice for my welding projects. This rod is designed for high-quality stainless steel welding, and its versatility allows it to perform well in a variety of applications. Whether you're working in the automotive or fabrication industry, the 309 Tig Rod provides excellent arc stability and a smooth finish, which is key for achieving professional results. Purchasing in bulk? I get it – timing and cost matter. That's why I appreciate how competitively priced these rods are for B2B buyers. With durable performance and easy handling, this rod is a wise investment for any welding operation. It's reliable and helps save time on repairs, ensuring efficiency. Trust me, when you try the 309 Tig Rod, you’ll see the difference in quality and performance that will elevate your projects.

309 Tig Rod Market Leader Guarantees Peak Performance

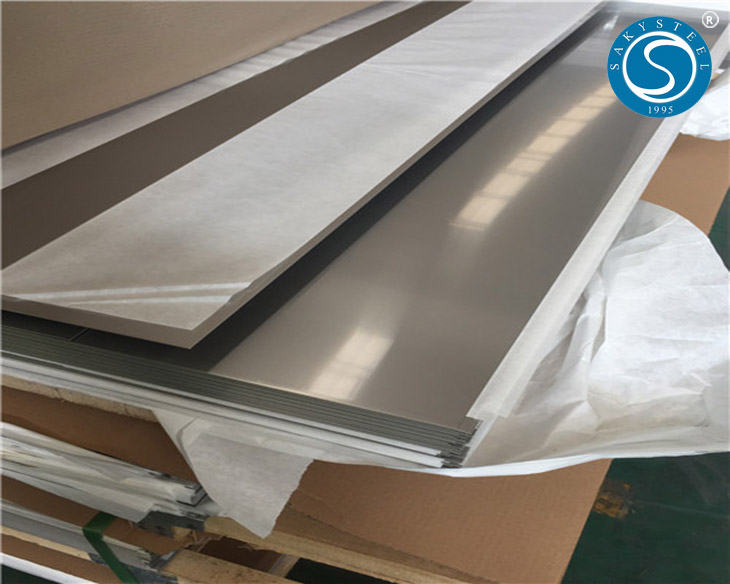

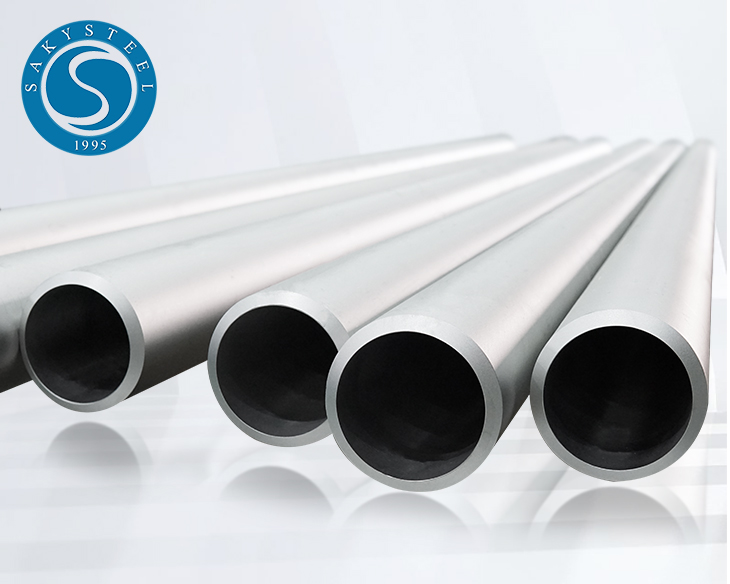

In the competitive landscape of welding materials, the 309 TIG rod stands out as a leader, ensuring peak performance for various industrial applications. Designed for optimum versatility, this rod excels in joining dissimilar metals, particularly stainless steel to carbon steel, which is crucial for many engineering projects. With a chemical composition that prioritizes corrosion resistance and strength, it delivers not just in effectiveness but also longevity, minimizing downtime during operations. Beyond its mechanical properties, the 309 TIG rod emphasizes productivity and ease of use for welders, allowing for smoother arcs and superior bead appearance. This focus on user experience translates to reduced effort and enhanced results, making it the preferred choice for skilled professionals across the globe. As industries increasingly prioritize efficiency without compromising on quality, this rod has made a significant impact on welding practices. For global procurement specialists, embracing top-tier welding consumables like the 309 TIG rod is an investment in reliability. Ensuring peak performance under diverse working conditions can enhance productivity and profitability, allowing businesses to maintain a competitive edge. As market demands evolve, selecting a welding solution that guarantees superior results is essential for fostering innovation and achieving operational excellence.

309 Tig Rod Market Leader Guarantees Peak Performance

| Rod Type | Material | Diameter (mm) | Length (m) | Tensile Strength (MPa) | Application |

|---|---|---|---|---|---|

| ER70S-6 | Mild Steel | 1.6 | 1.0 | 450 | General Welding |

| ER308L | Stainless Steel | 1.2 | 1.5 | 580 | Food Industry |

| ER309 | Stainless Steel | 1.0 | 1.0 | 620 | High-Temperature Applications |

| ER7018 | Low-Hydrogen Electrode | 3.2 | 2.5 | 600 | Structural Welding |

| ER80S-D2 | Nickel Alloy | 1.6 | 1.0 | 750 | High-Strength Applications |

Related Products