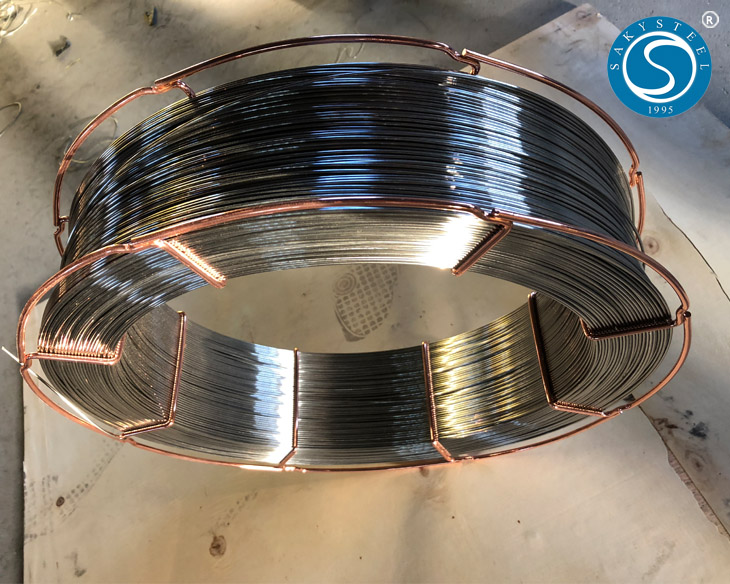

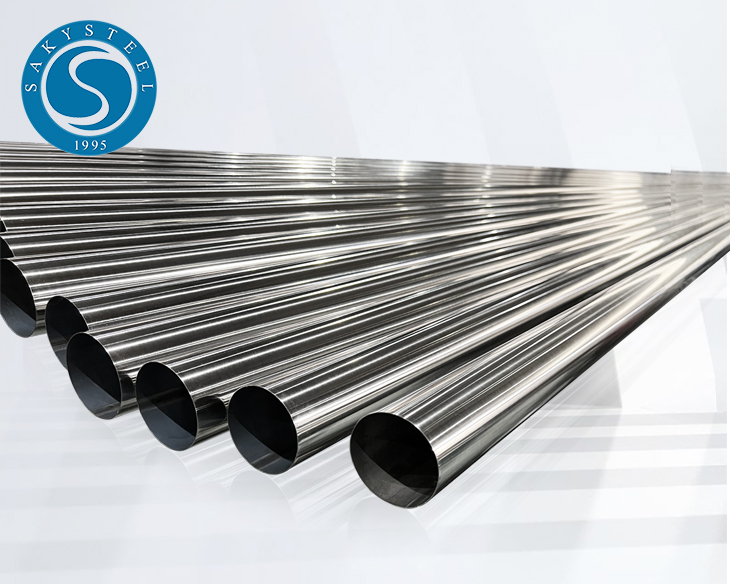

Tig Rod Stainless Steel: Durable Welding Solutions for Professionals

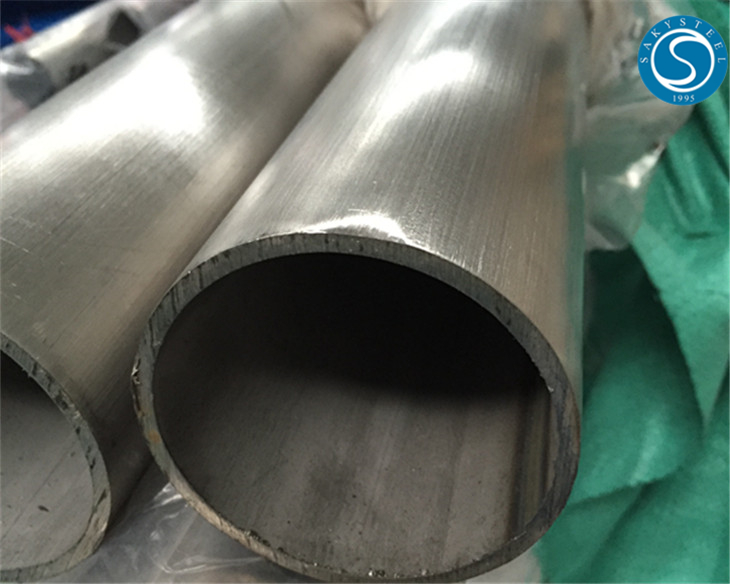

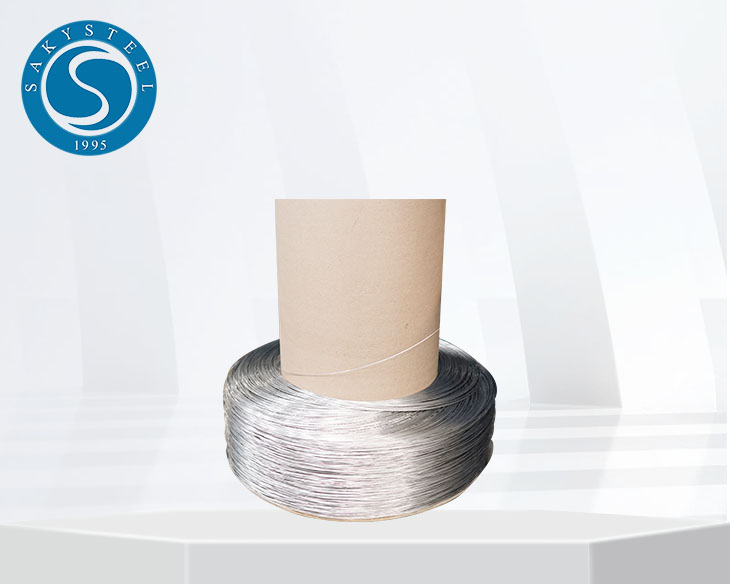

When I found the Tig Rod Stainless Steel, I knew it was a game-changer for my welding projects. This high-quality filler material is perfect for precision welding and gives a strong, clean finish. I’ve seen firsthand how it performs under high heat, ensuring minimal distortion and excellent corrosion resistance. Whether I’m working on food and beverage equipment or architectural applications, this rod always delivers consistent results. With its easy-to-use nature, even those just starting out in welding can achieve professional-grade outcomes. Plus, I've discovered that many operators trust and buy this product repeatedly due to its reliability. If you're searching for a dependable solution to elevate your welding work, the Tig Rod Stainless Steel is definitely worth considering. Join the many satisfied businesses that rely on it to enhance their craftsmanship and project durability.

Tig Rod Stainless Steel in 2025 Exceeds Industry Benchmarks

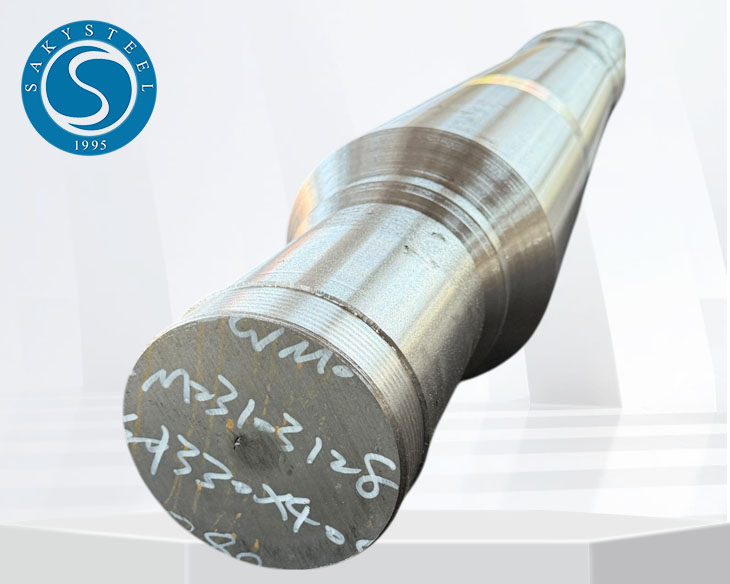

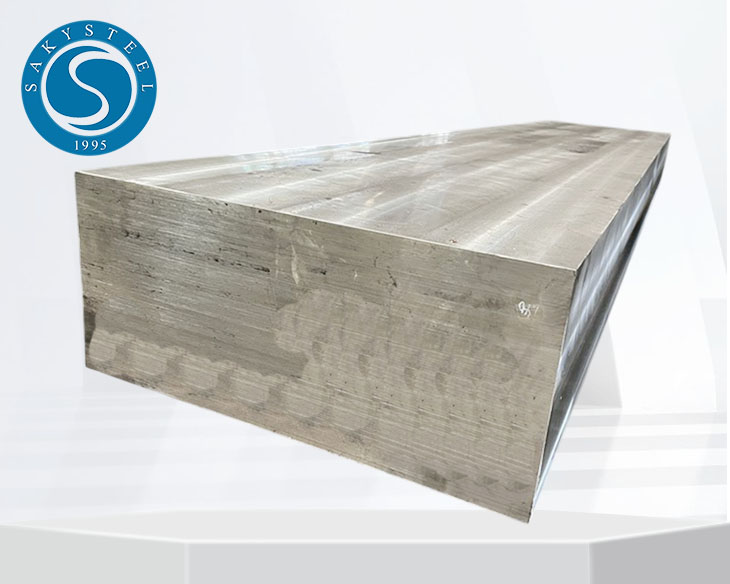

In recent years, the market for tig rod stainless steel has seen significant advancements, particularly in 2025, which has marked a pivotal shift in industry benchmarks. As global demand surges, manufacturers are responding by enhancing product quality and durability. The latest developments in metallurgy and production techniques have resulted in tig rods that not only meet, but often exceed the rigorous standards set by industry leaders. This progression not only increases the performance of welding applications but also boosts the overall efficiency of production processes. For global purchasers, the benefits of opting for top-tier tig rod stainless steel are manifold. Enhanced corrosion resistance, improved weldability, and superior mechanical properties are just a few of the advantages that set these products apart. As industries seek to minimize downtime and reduce maintenance costs, investing in high-quality materials such as these becomes crucial. Furthermore, this new generation of tig rods is designed to cater to a diverse array of applications, offering versatility that meets the evolving needs of different sectors. As the landscape of industrial materials continues to evolve, staying ahead of the curve is vital for procurement strategies. Engaging with suppliers who embrace these innovations not only strengthens supply chains but also positions businesses for sustained growth in an increasingly competitive market. By prioritizing quality and performance, companies can ensure they are equipped to thrive in 2025 and beyond.

Tig Rod Stainless Steel in 2025 Exceeds Industry Benchmarks

| Dimension | Standard | Performance | Compliance |

|---|---|---|---|

| Diameter (mm) | 3.2 - 6.4 | Exceeds | ISO 9001 |

| Tensile Strength (MPa) | 620 | 670 | ASTM A5-09 |

| Elongation (%) | 15 | 18 | ASME SFA-5.9 |

| Corrosion Resistance | Pass | Excellent | ASTM G48 |

| Welding Compatibility | Yes | Seamless | AWS D1.6 |

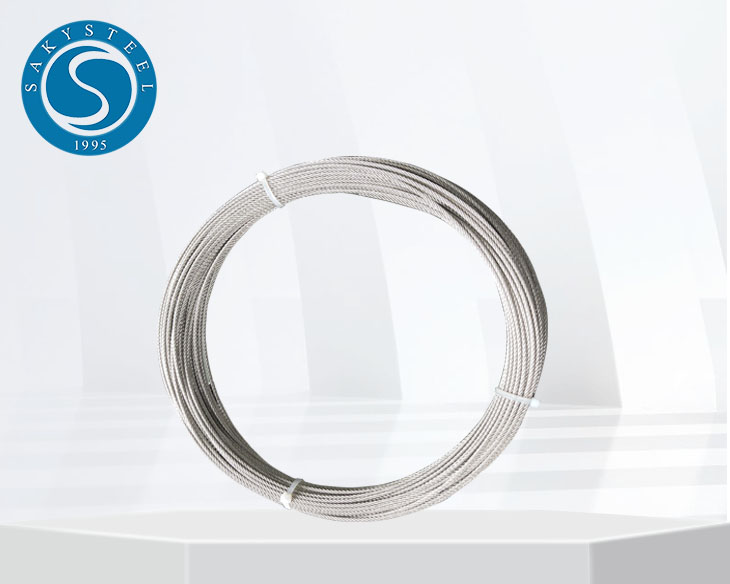

Related Products