Discover H11 Tool Steel: Ideal Selections for High-Performance Applications

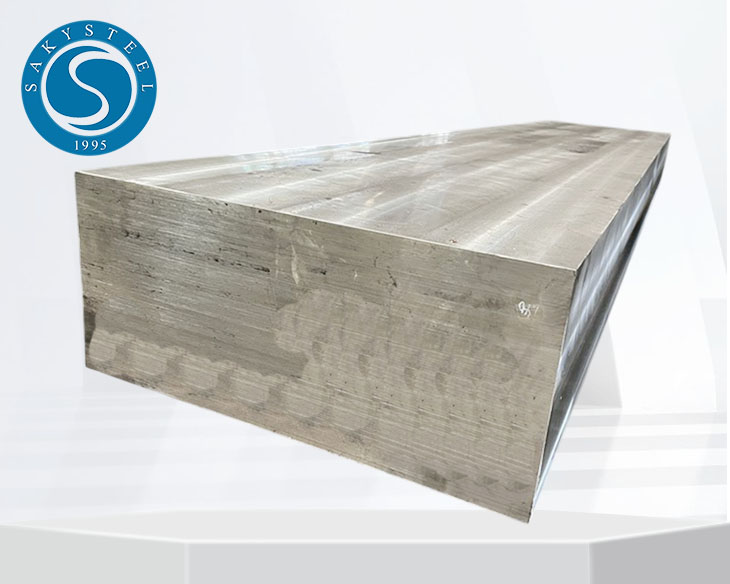

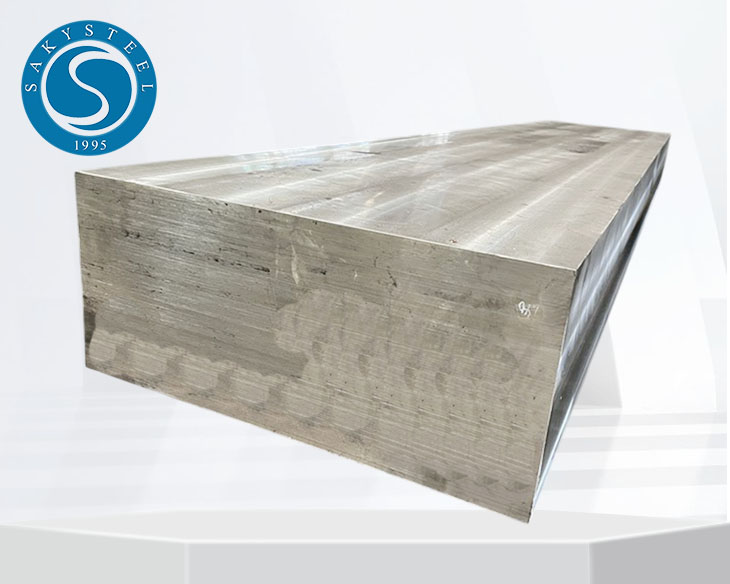

If you're in the market for H11 Tool Steel, you’ve come to the right place. I totally understand the importance of choosing the right material for your applications, whether it's for hot forming dies or other demanding environments. This high-quality tool steel offers excellent toughness, wear resistance, and can withstand high temperatures, making it perfect for a range of industrial uses. What sets our H11 Tool Steel apart is its consistency in performance and reliability. I’ve seen firsthand how it helps cut down on downtime in production due to its superior durability. Plus, you can rest easy knowing it's compliant with industry standards that matter to your operations. No matter the scale of your project, the quality and dependability of H11 Tool Steel will help your business thrive. Let’s make a smart investment that pays off in the long run! Interested in placing an order or have a question? Just reach out!

H11 Tool Steel Market Leader Leads the Global Market

In the competitive landscape of tool steel, H11 tool steel has emerged as a market leader, offering remarkable versatility and performance in various applications. Known for its excellent toughness, durability, and high heat resistance, H11 is the go-to choice for manufacturers who require reliable materials for demanding environments. As global markets expand and production needs evolve, the demand for high-quality tool steel has surged, positioning H11 as a critical component in sectors such as aerospace, automotive, and manufacturing. As procurement professionals look to invest in high-performance materials, understanding the benefits of H11 tool steel is essential. Its ability to withstand extreme temperatures and maintain hardness makes it ideal for hot work applications, including forging and die-casting. Furthermore, the evolving technological advancements in metallurgy enhance its properties, ensuring that manufacturers receive increasingly superior products. The global network of suppliers and manufacturers is adapting to meet the rising demand efficiently, establishing competitive pricing and innovative solutions for buyers worldwide. In conclusion, H11 tool steel not only sets the standard for quality and performance but also plays a pivotal role in the future of manufacturing and production processes. By investing in H11, businesses can ensure they are utilizing materials that support sustainability and innovation while meeting the demands of an ever-changing market. As the industry continues to grow, so does the importance of forming strong partnerships with reputable suppliers to secure a steady stream of high-quality materials.

H11 Tool Steel Market Overview

| Region | Market Share (%) | Growth Rate (2023-2028) (%) | Key Application |

|---|---|---|---|

| North America | 30 | 5.5 | Heavy Machinery |

| Europe | 25 | 4.7 | Automotive |

| Asia-Pacific | 35 | 6.2 | Construction |

| Latin America | 5 | 3.6 | Oil & Gas |

| Middle East & Africa | 5 | 4.0 | Aerospace |

Related Products