Best 309 Tig Welding Rod for Superior Welding Performance and Durability

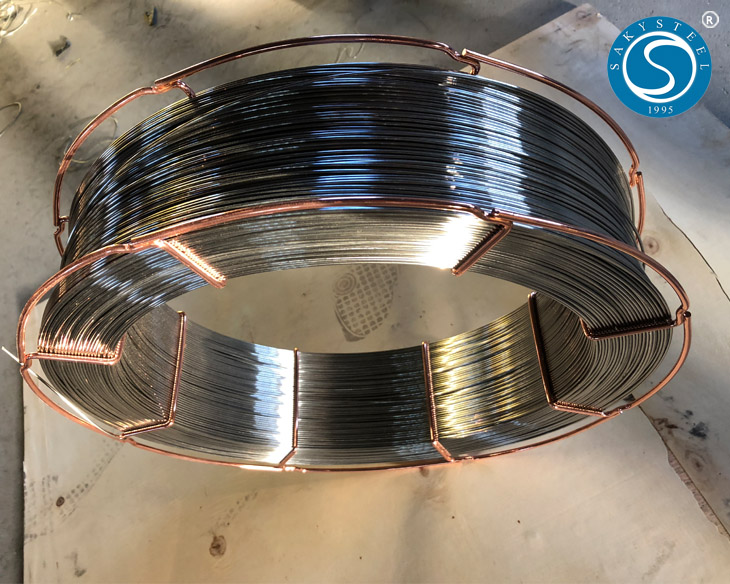

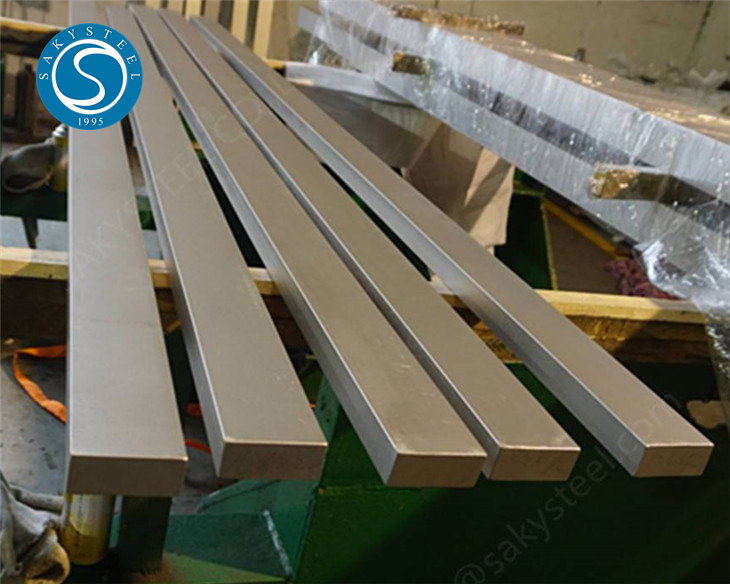

When it comes to versatile welding solutions, I can’t recommend the 309 Tig Welding Rod enough. Designed for a range of applications, this rod excels in stainless steel and dissimilar metal welding, making it a go-to choice for businesses like yours. Whether you're in heavy fabrication, automotive, or construction, I’ve found that the 309 rods deliver exceptional strength and durability. You can count on these rods to provide a smooth arc and minimal spatter, which means less cleanup time for my team and more productivity. With easy handling and outstanding corrosion resistance, they help maintain high quality in our projects. Plus, these rods save time and reduce material costs while achieving a clean finish. If you’re ready to elevate your welding projects, investing in 309 Tig Welding Rod is a smart choice. Let’s ensure your projects meet the highest standards with reliable materials that won't let you down.

309 Tig Welding Rod Winning in 2025 Where Service Meets Innovation

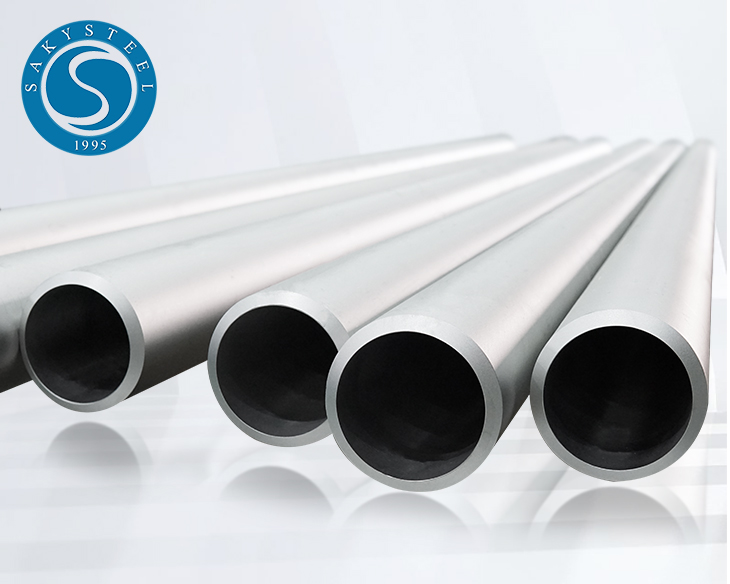

As we look ahead to 2025, the welding industry is poised for transformative advancements, particularly with products like the 309 TIG welding rod. This rod represents the ideal fusion of service and innovation, ensuring that global procurement professionals find a trustworthy solution for their diverse welding needs. The 309 TIG rod is distinguished by its exceptional versatility, making it suitable for welding dissimilar metals, including stainless steels and nickel alloys. As industries evolve and demand higher quality and efficiency, this product stands ready to meet those requirements. In an ever-changing marketplace, the emphasis on superior service cannot be overstated. Procurement professionals are seeking partners who not only provide high-quality products but also support their operations through expert guidance and tailored solutions. The 309 TIG welding rod is backed by extensive technical knowledge, ensuring that users can effectively utilize it for optimal results. This commitment to customer service, combined with innovative manufacturing processes, guarantees a product that is reliable and efficient. The future of welding is undoubtedly tied to advancements that enhance performance while prioritizing safety and sustainability. As we progress toward 2025, the focus will be on developing welding solutions that adhere to global standards and meet the needs of various industries. With the 309 TIG welding rod, both service excellence and innovative design converge, positioning it as a key player in the global welding market. Embracing these innovations not only ensures superior welding outcomes but also fosters stronger supply chain relationships in an increasingly competitive landscape.

309 Tig Welding Rod Winning in 2025 Where Service Meets Innovation

| Feature | Description | Innovation Aspect | Service Offering |

|---|---|---|---|

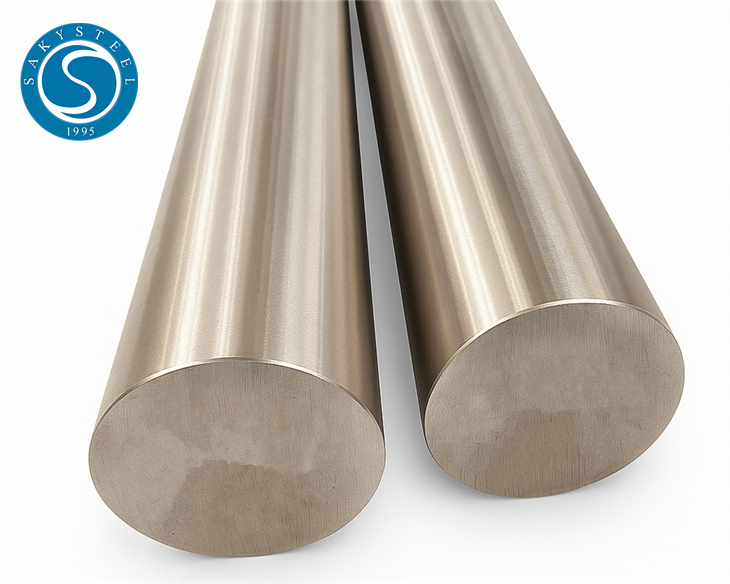

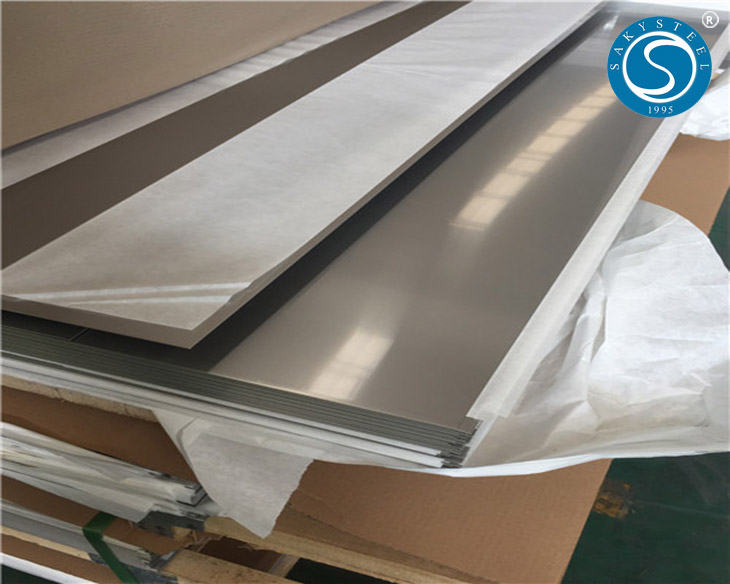

| Material Composition | High-quality tungsten alloy for enhanced performance. | Advanced metallurgy for improved durability. | Comprehensive technical support for users. |

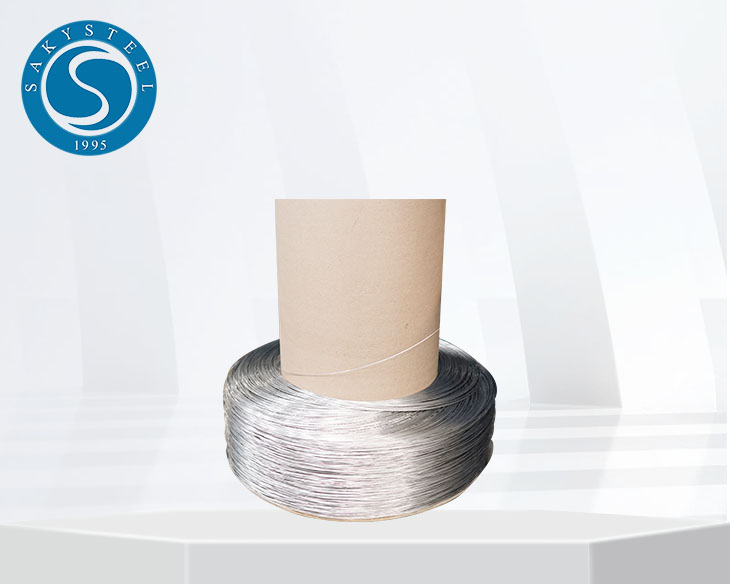

| Diameter Options | Available in multiple diameters ranging from 1.0mm to 3.2mm. | Versatility for different welding applications. | Personalized recommendations for projects. |

| Welding Performance | Excellent arc stability and minimal spatter. | Enhanced technology for cleaner welds. | Ongoing training sessions for best practices. |

| Packaging | Eco-friendly packaging solutions. | Sustainable practices being implemented. | Prompt delivery and environmentally conscious solutions. |

| User Feedback | Positive reviews from welding professionals. | Constant innovation based on user input. | Customer engagement and satisfaction surveys. |

Related Products