304 Stainless Hlau Tube Vuam

Lus piav qhia luv luv:

| Specifications ntawmStainless hlau welded yeeb nkab: |

Seamless Pipes & Tubes Loj:1/8 "NB-24" NB

Specifications:ASTM A / ASME A249, A268, A269, A270, A312, A790

Qib:304, 304, 316, 316L, 321, 409L

Ntev:5.8M, 6M & Ntev Ntev

Sab nraud txoj kab uas hla:6.00 hli OD txog 1500 hli OD

Thickness :0.3 hli-20mm,

Teem caij:SCH 5, SCH 10, SCH 40, SCH 80, SCH 80S

Nto tiav:Mill Finish, Polishing (180 #, 180 # hairline, 240 # hairline, 400 #, 600 #), Daim iav thiab lwm yam

Hom:Welded, EFW, ERW

Daim ntawv:Hloov, Square, Rectangle

Xaus:Plain End, Beveled End

| Stainless hlau 304/304L Welded Pipes sib npaug qib: |

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SIB 304 | 1.4301 ib | S30400 | TIAB SA 304 | 30 4s31 | 08J18J 10 | Z7CN18-09 | X5CrNi18-10 |

| SWB 304L | 1.4306/1.4307 | S30403 | SUS 304 L | 3 304s11 | 03j18j 11 | Z3CN18-10 | X2CrNi18-9 / X2CrNi19-11 |

| SS 304 / 304L Welded Pipes Chemical Composition thiab Mechanical Properties: |

| Qib | C | Mn | Si | P | S | Cr | Ni |

| SIB 304 | 0.08 max | 2 max | 0.75 max | 0.045 max | 0.030 max | 18–20 : kuv | 8–11 |

| SWB 304L | 0.035 max | 2 max | 1.0 max | 0.045 max | 0.03 max | 18–20 : kuv | 8–13 |

| Qhov ntom | Melting Point | Tensile zog | Yield zog (0.2% Offset) | Elongation |

| 8.0 g / cm3 | 1400 ° C (2550 ° F) | Psi - 75000, MPa - 515 | Psi - 30000, MPa - 205 | 35% |

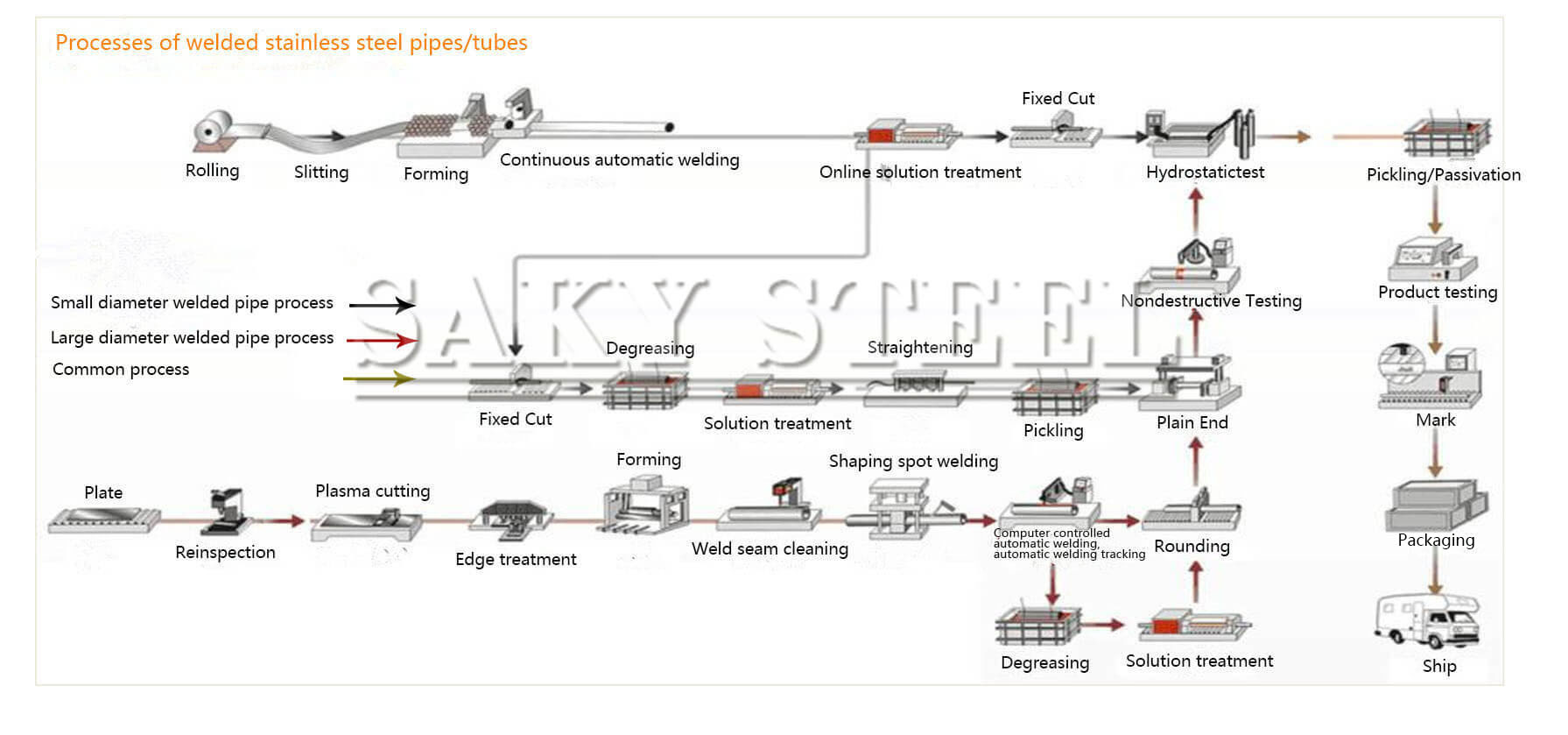

| Cov txheej txheem ntawm welded stainless hlau kav / raj: |

| Surface Finish Options: |

Peb muab ob hom kev txhuam hniav kom tau raws li qhov sib txawv ntawm cov hniav thiab kev ua haujlwm:

Ncaj plaub hau (Longitudinal txhuam):

Cov nplej khiav raws qhov ntev ntawm lub raj, tsim kom muaj kev sib luag thiab tsis tu ncua kev pom. Zoo tagnrho rau elevator kho kom zoo nkauj, architectural handrails, rooj tog tubing, thiab lwm yam high-end daim ntaub ntawv.

Cross Hairline (Transverse Txhuam):

Cov qoob loo puag ncig lub raj lub voj voog, muab qhov tshwj xeeb zoo rau qhov kawg-cap fittings, cov khoom siv, thiab kev tsim kho kom zoo nkauj.

|  |

| Hla Plaub hau | Ncaj plaub hau |

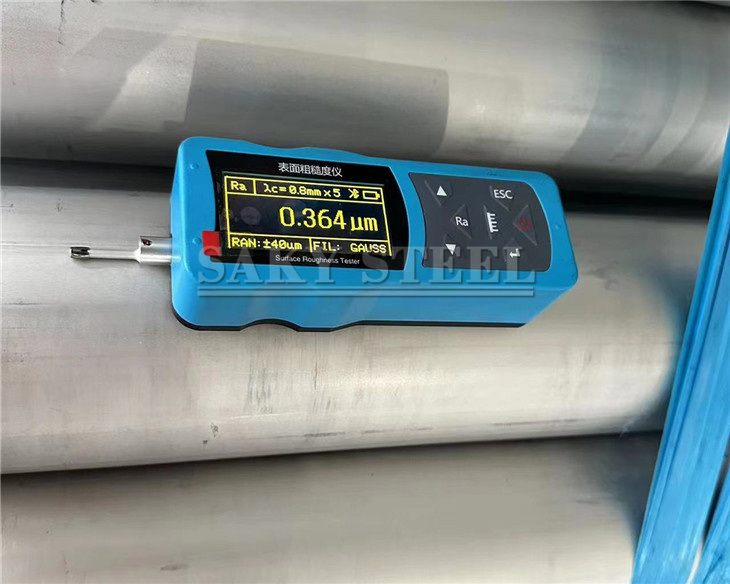

| 304 Stainless Hlau Tubing Weld Roughness xeem |

Ntawm SAKY STEEL peb ua nruj roughness ntsuam xyuas ntawm stainless hlau kav los xyuas kom meej ib tug du thiab zoo ib yam uas raws li thoob ntiaj teb cov qauv. Cov yeeb nkab roughness yog qhov tseem ceeb uas cuam tshuam rau kev ua haujlwm zoo corrosion thiab tag nrho kev ua haujlwm hauv cov ntawv thov tseem ceeb.

Peb siv cov cuab yeej precision los ntsuas qhov roughness qhov tseem ceeb kom ntseeg tau tias tag nrho cov kav dej ua tau raws li tus neeg yuav tsum tau ua rau smoothness thiab tiav. Peb cov kav dej yog qhov zoo tagnrho rau cov khoom siv tshuaj lom neeg ua dej hiav txwv thiab cov qauv kev lag luam uas qhov chaw zoo yog qhov tseem ceeb.

|  |

| 304 Stainless Hlau Welded Tube Surface Test |

Qhov saum npoo ntawm cov kav hlau stainless yog qhov tseem ceeb rau kev ua tau zoo thiab zoo li. Ntawm SAKY STEEL peb nruj me ntsis tswj qhov zoo ntawm cov txheej txheem tshuaj xyuas. Daim duab qhia tau hais tias muaj kev sib piv meej ntawm cov kav dej tsis zoo uas pom qhov tsis xws luag thiab peb cov kav dej zoo nrog cov kav dej du thiab zoo ib yam.

Peb cov kav dej stainless hlau tsis pub muaj cov kab nrib pleb khawb khawb thiab vuam cov cim kom ntseeg tau zoo corrosion kuj thiab kev ntseeg tau. Cov kav dej no tau siv dav hauv kev siv tshuaj lom neeg marine thiab cov qauv siv qhov chaw uas muaj kev ncaj ncees ntawm qhov chaw.

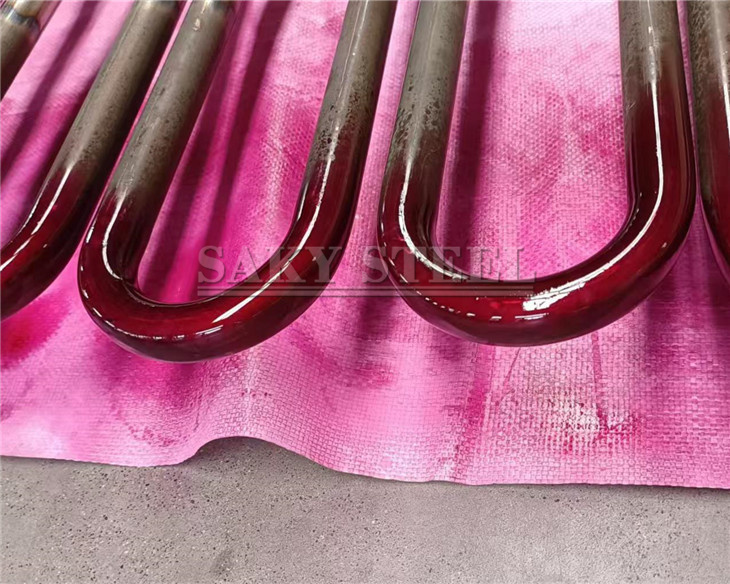

| 304 Stainless Hlau Welded Yeeb Nkab PT Test |

SAKY STEEL ua qhov kev ntsuam xyuas PT ntawm cov kav hlau tsis muaj steel thiab cov khoom ua ib feem ntawm peb cov txheej txheem tswj xyuas nruj. PT yog ib txoj kev kuaj uas tsis muaj kev puas tsuaj uas siv los txheeb xyuas qhov tsis xws luag xws li tawg porosity thiab suav nrog uas tsis pom ntawm qhov muag liab qab.

Peb cov kws tshuaj ntsuam xyuas tau siv cov khoom zoo siab thiab cov khoom tsim tawm los xyuas kom meej thiab txhim khu kev qha. Tag nrho cov txheej txheem PT ua raws li cov qauv thoob ntiaj teb thiab cov neeg siv khoom tshwj xeeb uas lav cov khoom muaj kev nyab xeeb thiab kev ua haujlwm.

|  |

| Weld Seam Tshuaj xyuas ntawm 304 Stainless Hlau Welded Yeeb Nkab |

Stainless hlau yeeb nkab weld seam tshuaj xyuas xyuas kom meej tias tag nrho cov welded pob qij txha ua tau raws li qhov yuav tsum tau muaj cov qauv zoo thiab kev nyab xeeb. Cov txheej txheem tshuaj xyuas yog tsom rau kev kuaj xyuas qhov chaw thiab sab hauv xws li cov kab nrib pleb, porosity, slag inclusions, tsis muaj fusion, thiab kev nkag tsis tiav. Cov txheej txheem feem ntau suav nrog kev tshuaj xyuas qhov muag, tshuaj ntsuam xyuas qhov muag, kuaj ultrasonic, thiab kuaj hluav taws xob. Txhua txoj kev raug xaiv raws li cov khoom siv yeeb nkab, phab ntsa thickness, thiab cov kev pabcuam. Txhua qhov kev tshuaj xyuas yog ua raws li cov qauv thoob ntiaj teb xws li ASME, ASTM, thiab ISO los lav qhov kev ncaj ncees thiab kev ua haujlwm ntawm cov kav dej welded.

|  |

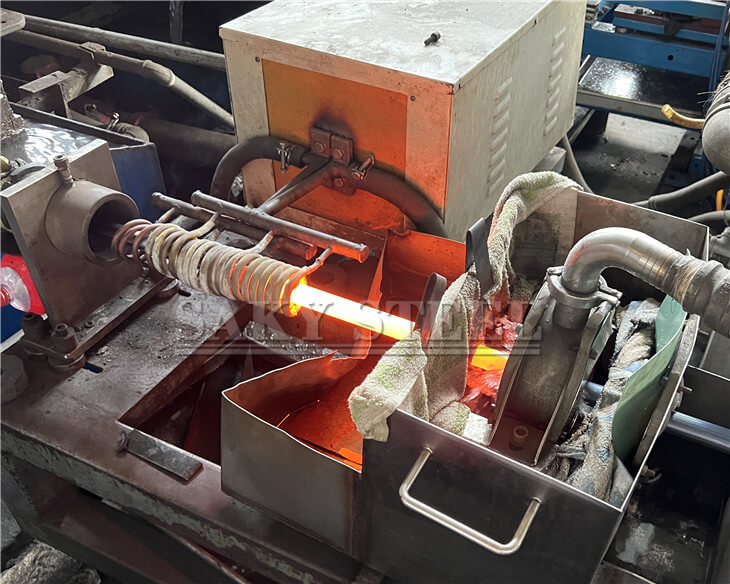

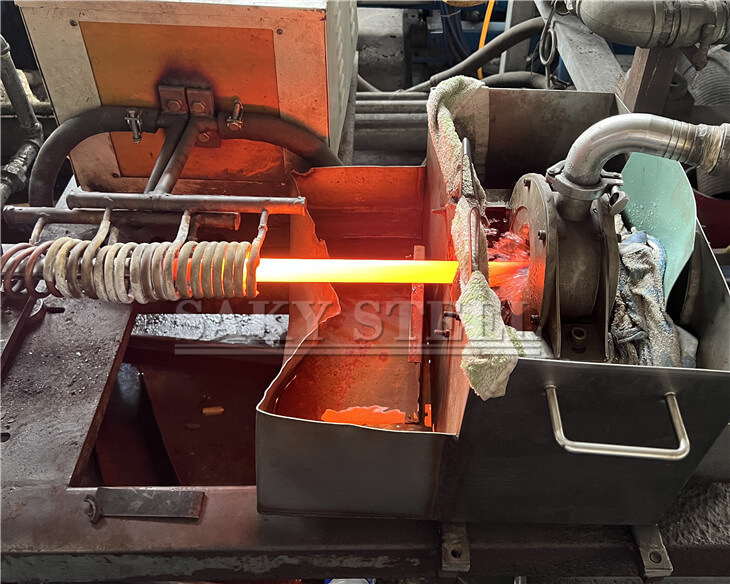

| In-line Solution Annealing ntawm Stainless Hlau Welded Yeeb Nkab |

In-line tov annealing ntawm stainless hlau yeeb nkab yog ib tug tas mus li kev kho cua sov txheej txheem siv thaum lub sij hawm ntau lawm kom ua tau ib tug uniform austenitic microstructure thiab txhim khu corrosion kuj. Cov yeeb nkab yog rhuab mus rau qhov kev daws teeb meem annealing kub, feem ntau ntawm 1000 ° C thiab 1150 ° C, thiab tom qab ntawd txias txias, feem ntau siv dej quenching lossis yuam cua txias. Cov txheej txheem no dissolves carbide precipitates thiab tiv thaiv intergranular corrosion, xyuas kom meej cov khoom thiab nto zoo raws li thoob ntiaj teb cov qauv. In-line tov annealing txhim kho kev tsim khoom zoo thaum tswj xyuas cov khoom lag luam zoo ib yam.

|  |

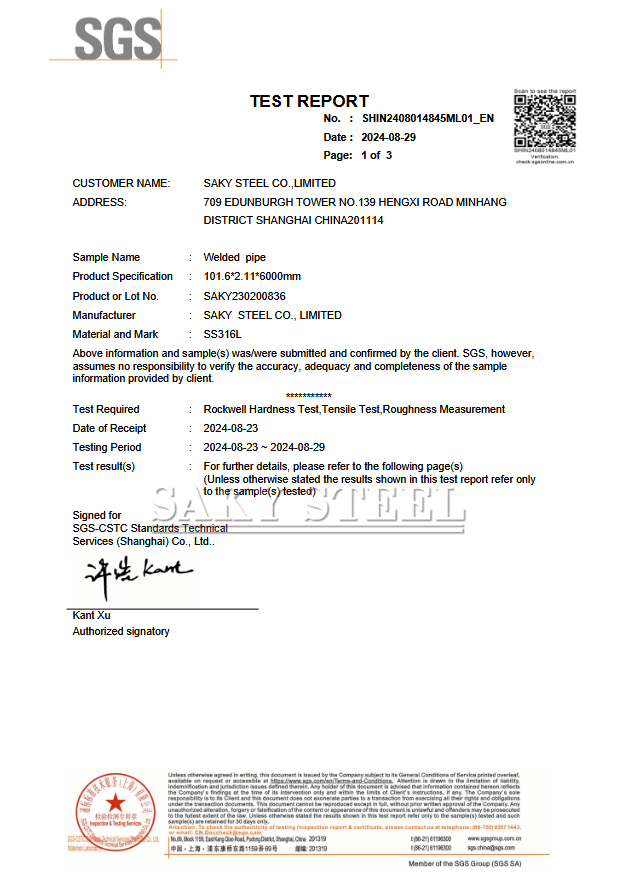

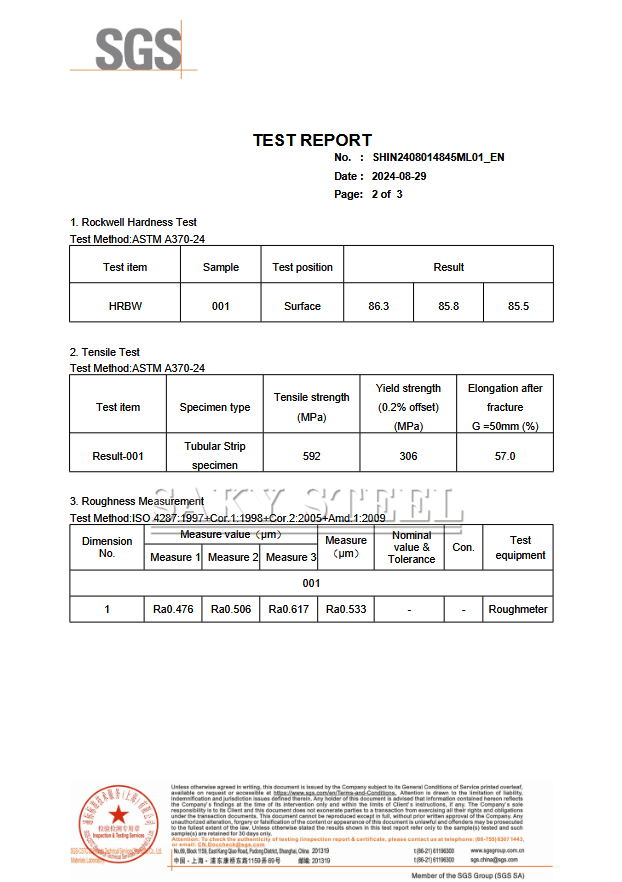

| Welded yeeb nkab Test Report |

Cov khoom siv kho tshuab ntawm cov khoom tau raug kuaj raws li ASTM A370 Standard Test Methods thiab Definitions for Mechanical Testing of Steel Products. Tag nrho cov txiaj ntsig kev xeem, suav nrog lub zog tensile, lub zog tawm los, elongation, thiab hardness, ua raws li cov kev cai tshwj xeeb thiab raug sau ua ib feem ntawm daim ntawv pov thawj no kom ua tau raws li cov qauv siv tau thiab cov neeg siv khoom tshwj xeeb.

|  |  |

| Vim Li Cas Xaiv Peb |

1. Koj tuaj yeem tau txais cov khoom zoo meej raws li qhov koj xav tau ntawm tus nqi tsawg kawg nkaus.

2. Peb kuj muab Reworks, FOB, CFR, CIF, thiab qhov rooj rau qhov rooj tus nqi xa khoom. Peb xav kom koj ua deal rau shipping uas yuav zoo heev.

3. Cov ntaub ntawv uas peb muab yog muaj tseeb tiag, txoj cai los ntawm raw cov ntaub ntawv xeem daim ntawv pov thawj mus rau qhov kawg dimensional nqe lus.

4. e lav muab cov lus teb tsis pub dhau 24 teev (feem ntau hauv tib lub sijhawm)

5. Koj tuaj yeem tau txais cov khoom lag luam, cov khoom xa tuaj nrog lub sijhawm tsim khoom tsawg.

6. Peb muaj siab rau peb cov neeg muas zaub. Yog tias nws yuav tsis tuaj yeem ua tau raws li koj cov kev xav tau tom qab kuaj xyuas tag nrho cov kev xaiv, peb yuav tsis ntxias koj los ntawm kev cog lus tsis tseeb uas yuav tsim kev sib raug zoo rau cov neeg siv khoom.

| SAKY STEEL'S Quality Assurance (nrog rau kev puas tsuaj thiab tsis muaj kev puas tsuaj) |

1. Visual Dimension Test

2. Kev tshuaj xyuas cov tshuab xws li tensile, Elongation thiab txo qhov chaw.

3. Kev xeem loj

4. Tshuaj ntsuam xyuas

5. Kev sim hardness

6. Pitting tiv thaiv kuaj

7. Kev xeem Flaring

8. Dej-Jet Test

9. Kev Xeem Penetrant

10. X-ray kuaj

11. Intergranular Corrosion Testing

12. Kev soj ntsuam cuam tshuam

13. Metallography Experimental Test

| SAKY STEEL Ntim: |

1. Kev ntim khoom yog qhov tseem ceeb heev tshwj xeeb tshaj yog nyob rau hauv rooj plaub ntawm kev xa khoom thoob ntiaj teb uas cov khoom xa tuaj dhau los ntawm ntau txoj kev mus txog qhov kawg, yog li peb muab kev txhawj xeeb tshwj xeeb txog kev ntim khoom.

2. Saky Steel ntim peb cov khoom hauv ntau txoj hauv kev raws li cov khoom lag luam. Peb ntim peb cov khoom nyob rau hauv ntau txoj kev, xws li,

Daim ntawv thov:

1. Auto qhov chaw, khoom siv kho mob

2. Thaum tshav kub kub Exchanger, zaub mov kev lag luam

3. Kev ua liaj ua teb, hluav taws xob, tshuaj

4. Coal tshuaj lom neeg; Kev tshawb nrhiav roj thiab roj

5. Petroleum refining, Natural gas; Tswv yim