304 Stainless Steel Tube Welding

Tlhaloso e Khutšoanyane:

| Litlhaloso tsaphala e entsoeng ka tšepe e sa hloekang: |

Liphaephe tse Seamless & Boholo ba Liphaephe :1 / 8″ NB – 24″ NB

Litlhaloso :ASTM A/ASME A249, A268, A269, A270, A312, A790

Kereiti:304, 304L, 316, 316L, 321, 409L

Bolelele :5.8M,6M & Bolelele bo Hlokehang

Kantle Diameter :6.00 limilimithara OD ho fihla ho 1500 limilimithara OD

Botenya :0.3-20 limilimithara,

Kemiso :SCH 5, SCH10, SCH 40, SCH 80, SCH 80S

Surface Finish :Mill Finish, polishing(180#,180# hairline,240# hairline,400#,600#), Seipone jj.

Mefuta :E cheselitsoe, EFW, ERW

Foromo :Rtoa, Sekwere, Rectangle

QETA :Qetello e Ntle, Qetello e Beveled

| Stainless Steel 304/304L Liphaephe tse Cheselitsoeng Mephato e Tšoanang: |

| TS'ELISO | WERKSTOFF NR. | UNS | JIS | BS | GOST | HLOMPHO | EN |

| SS304 | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18-09 | X5CrNi18-10 |

| SS 304L | 1.4306 / 1.4307 | S30403 | SUS 304L | 3304S11 | 03Х18Н11 | Z3CN18-10 | X2CrNi18-9 / X2CrNi19-11 |

| SS 304 / 304L Liphaephe tse Welded Sebopeho sa Lik'hemik'hale le thepa ea Mochini: |

| Kereiti | C | Mn | Si | P | S | Cr | Ni |

| SS304 | 0.08 max | 2 max | 0.75 boholo | 0.045 boholo | 0.030 boholo | 18-20 | 8 - 11 |

| SS 304L | 0.035 boholo | 2 max | 1.0 boholo | 0.045 boholo | 0.03 boholo | 18-20 | 8-13 |

| Botenya | Melting Point | Matla a tšepe | Matla a Hlahisa (0.2%Offset) | Elongation |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi - 75000 , MPa - 515 | Psi - 30000 , MPa - 205 | 35 % |

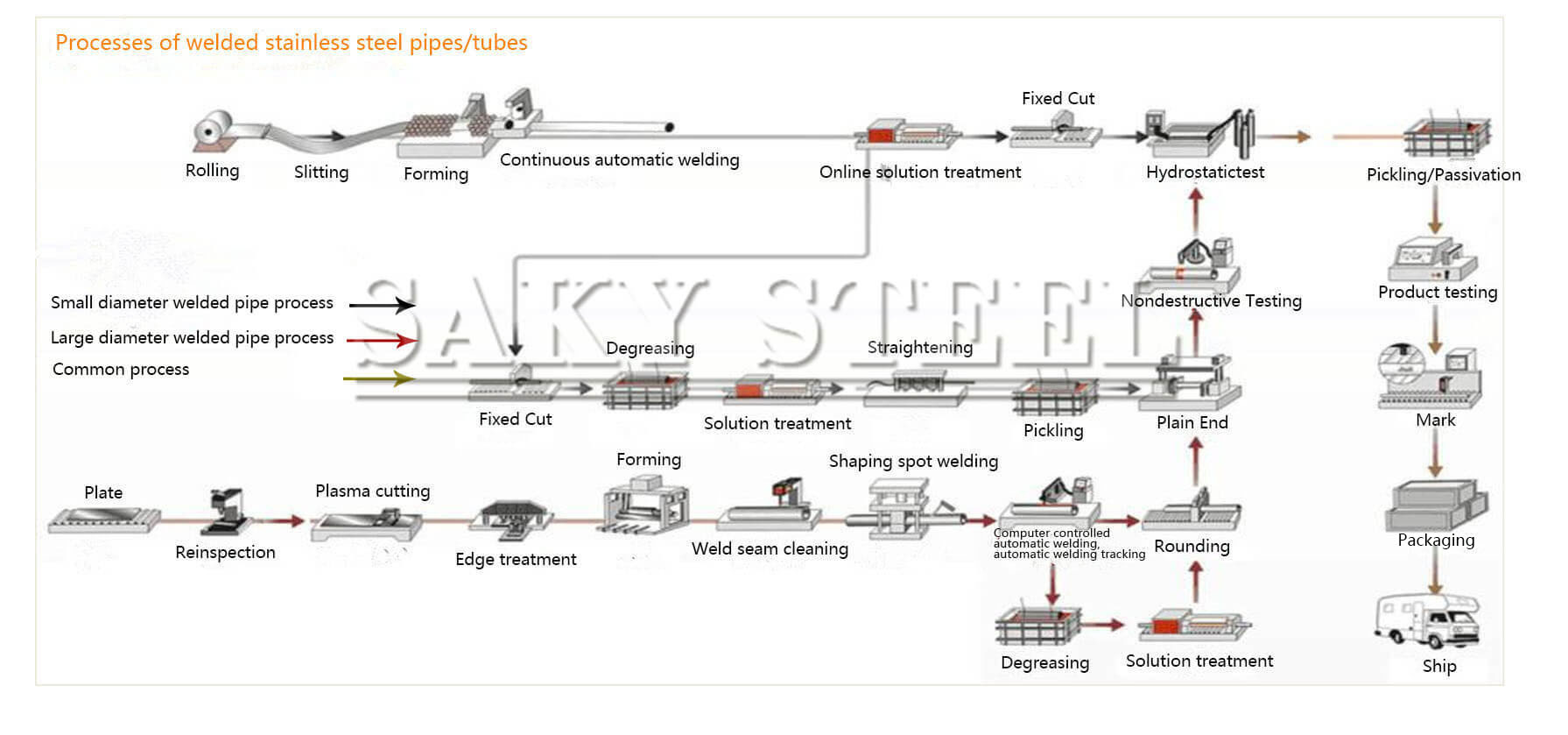

| Mekhoa ea ho etsa liphaephe/lithapo tsa tšepe tse cheselitsoeng: |

| Likhetho tsa Surface Finish: |

Re fana ka mefuta e 'meli ea litataiso tsa brashi ho fihlela litlhoko tse fapaneng tsa mekhabiso le ts'ebetso:

Mohala o otlolohileng oa Moriri (Borashe ba Longitudinal):

Lijo-thollo li matha ka bolelele ba tube, li etsa hore ho be le ponahalo e boreleli le e tsoelang pele. E loketse mokhabiso oa lifti, lithaelese tsa meralo ea meralo, lithapo tsa thepa ea ka tlung le lits'ebetso tse ling tsa maemo a holimo.

Cross Hairline (Transverse Brushing):

Mabele a pota-potile selikalikoe sa tube, a fana ka ponahalo e ikhethang bakeng sa li-end-cap fittings, likarolo tsa sebopeho, le mekhabiso e tloaelehileng ea mekhabiso.

|  |

| Cross Hairline | Moriri o otlolohileng |

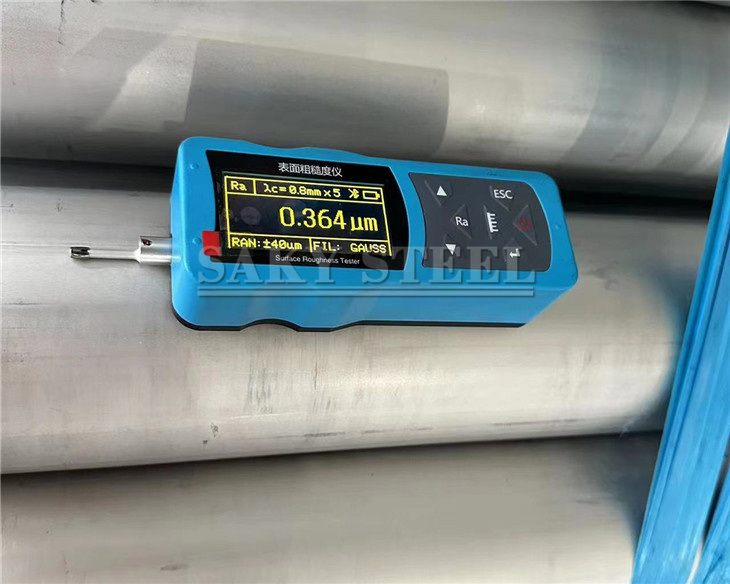

| 304 Stainless Steel Tubing Weld Roughness test |

Ho SAKY STEEL re etsa liteko tse thata tsa ho ba mahoashe liphaepheng tsa tšepe e sa hloekang ho etsa bonnete ba hore sebaka se boreleli se lumellana le maemo a machaba. Bokhopo ba liphaephe ke ntlha ea bohlokoa e amang ts'ebetso ea phallo ea kutu le ts'ebetso e akaretsang lits'ebetsong tsa bohlokoa.

Re sebelisa lisebelisoa tse nepahetseng ho lekanya boleng ba bokaholimo ho netefatsa hore liphaephe tsohle li fihlela litlhoko tsa bareki bakeng sa ho boreleli le ho qeta. Liphaephe tsa rona li loketse bakeng sa ho sebetsana le lik'hemik'hale tsa lijo tsa leoatleng le liindasteri tsa meralo moo boleng ba holim'a metsi bo leng bohlokoa.

|  |

| 304 Stainless Steel Welded Tube Surface Test |

Qetello ea bokaholimo ba liphaephe tsa tšepe e sa hloekang ke ea bohlokoa bakeng sa ts'ebetso le ponahalo. Ho SAKY STEEL re laola ka thata boleng ba bokaholimo ka mekhoa e tsoetseng pele ea tlhahlobo. Setšoantšo se bontša papiso e hlakileng pakeng tsa liphaephe tse mpe tsa holim'a metsi tse nang le mefokolo e bonahalang le liphaephe tsa rona tse ntle tsa holim'a metsi tse nang le qetello e boreleli le e ts'oanang.

Liphaephe tsa rona tsa tšepe tse sa hloekang ha li na mapetsong a mekoti le matšoao a cheseletso a netefatsang ho hanyetsa ho bola le ho ts'epahala. Liphaephe tsena li sebelisoa haholo lits'ebetsong tsa lik'hemik'hale tsa leoatleng le tsa meralo moo boleng ba holim'a metsi bo leng bohlokoa.

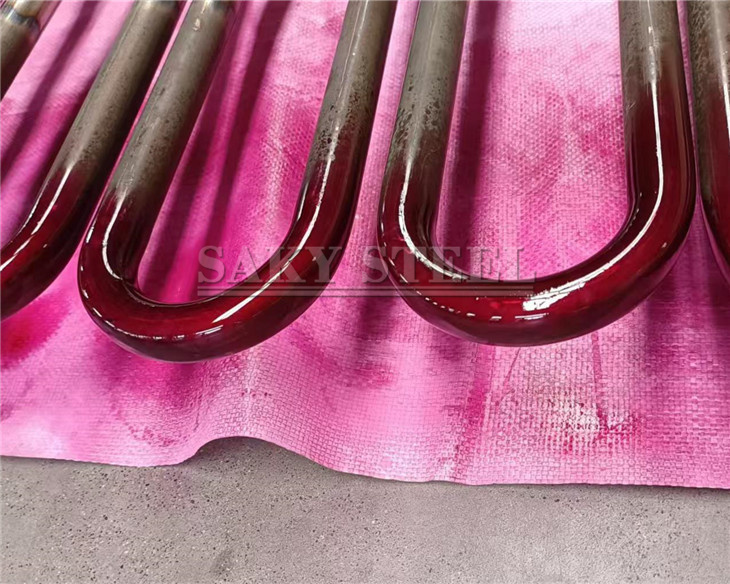

| 304 Stainless Steel Welded Pipe PT Test |

SAKY STEEL e etsa tlhahlobo ea PT e kenang ka har'a liphaephe le likarolo tsa tšepe e le karolo ea ts'ebetso ea rona e tiileng ea taolo ea boleng. PT ke mokhoa o sa senyeheng oa tlhahlobo o sebelisetsoang ho bona mefokolo ea holim'a metsi joalo ka cracks porosity le inclusions tse sa bonahaleng ka mahlo.

Bahlahlobi ba rona ba koetlisitsoeng ba sebelisa lisebelisoa tsa boleng bo holimo tse kenang le tsa nts'etsopele ho netefatsa liphetho tse nepahetseng le tse tšepahalang. Mekhoa eohle ea PT e latela maemo a machaba le litlhaloso tsa bareki tse netefatsang polokeho le ts'ebetso ea sehlahisoa.

|  |

| Tlhahlobo ea Weld Seam ea 304 Stainless Steel Welded Pipe |

Tlhahlobo ea seam ea phala ea tšepe e sa hloekang e tiisa hore manonyeletso ohle a cheselitsoeng a kopana le litekanyetso tse hlokahalang tsa boleng le polokeho. Ts'ebetso ea ho hlahloba e shebane le ho lemoha mefokolo e ka holimo le ea ka hare e kang mapetsong, porosity, slag inclusions, ho hloka fusion, le ho kenella ho sa phethoang. Mekhoa e tloaelehileng e kenyelletsa tlhahlobo ea pono, tlhahlobo e kenang ka dae, tlhahlobo ea ultrasonic, le tlhahlobo ea radiographic. Mokhoa o mong le o mong o khethoa ho latela thepa ea liphaephe, botenya ba lerako, le maemo a ts'ebeletso. Litlhahlobo tsohle li etsoa ho latela maemo a machaba a kang ASME, ASTM, le ISO ho netefatsa bots'epehi le ts'ebetso ea lipeipi tse cheselitsoeng.

|  |

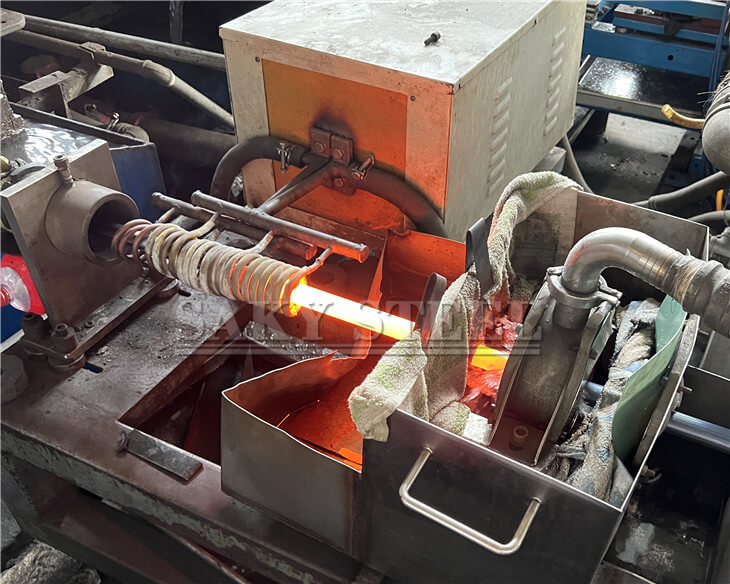

| Tharollo ea In-line Ho Aneloa ha Pipe e Tletseng Stainless Steel Welded |

Tharollo ea in-line annealing ea phala ea tšepe e sa hloekang ke ts'ebetso e tsoelang pele ea kalafo ea mocheso e sebelisoang nakong ea tlhahiso ho fihlela sebopeho sa austenitic microstructure e ts'oanang le ho matlafatsa ho hanyetsa kutu. Pipe e futhumatsoa ho mocheso o boletsoeng oa tharollo, hangata pakeng tsa 1000 ° C le 1150 ° C, 'me e ntan'o pholile ka potlako, hangata e sebelisa ho tima metsi kapa ho qobella moea o pholileng. Ts'ebetso ena e qhaqha li-carbide precipitates le ho thibela ho bola ha intergranular, ho netefatsa hore thepa ea mochine le boleng ba holim'a metsi li finyella litekanyetso tsa machaba. In-line solution annealing e ntlafatsa katleho ea tlhahiso ha e ntse e boloka ts'ebetso e tsitsitseng ea sehlahisoa.

|  |

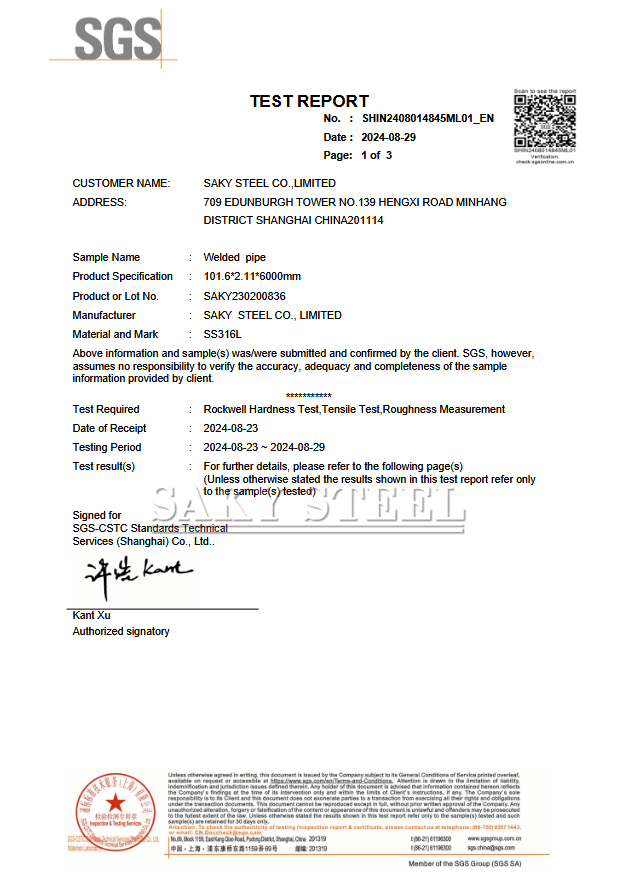

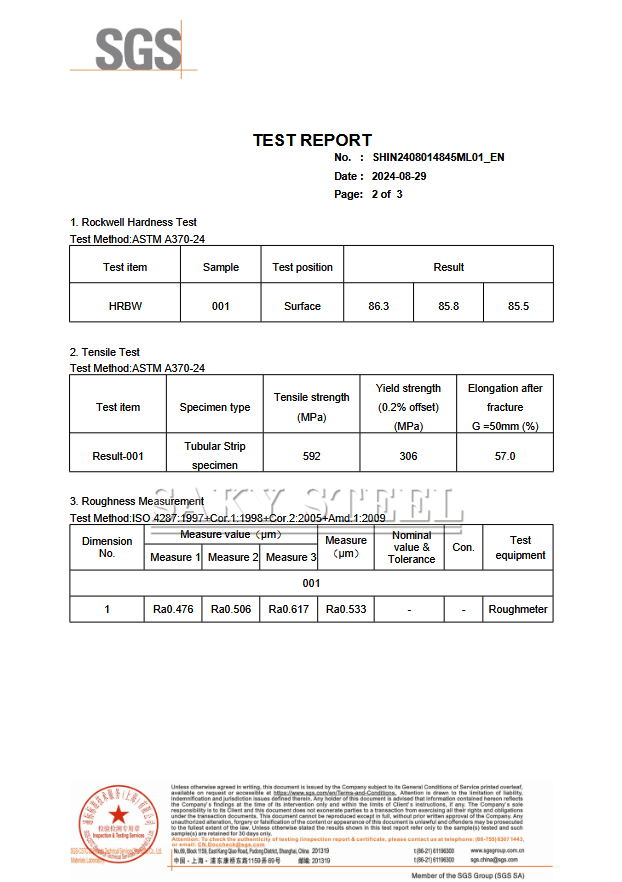

| Tlaleho ea Teko ea Peipi e cheselitsoeng |

Thepa ea mochini oa sehlahisoa e lekoa ho latela Mekhoa e Tloaelehileng ea Tlhahlobo ea ASTM A370 le Litlhaloso tsa Teko ea Mechini ea Lihlahisoa tsa tšepe. Liphetho tsohle tsa liteko, ho kenyeletsoa matla a ho tsieleha, matla a tlhahiso, bolelele le boima, li lumellana le litlhoko tse boletsoeng mme li ngotsoe e le karolo ea setifikeiti sena ho netefatsa ho lumellana le litekanyetso tse sebetsang le litlhaloso tsa bareki.

|  |  |

| Ke Hobane'ng ha U Re Khetha |

1. U ka fumana boitsebiso bo phethahetseng ho ea ka tlhokahalo ea hau bonyane theko e ka khonehang.

2. Re boetse re fana ka Reworks, FOB, CFR, CIF, le litheko tsa ho fana ka ntlo le ntlo. Re fana ka tlhahiso ea hore u etse tumellano ea ho tsamaisa thepa e tla u baballa haholo.

3. Thepa eo re fanang ka eona e ka netefatsoa ka botlalo, ho tloha ho setifikeiti sa tlhahlobo ea thepa e tala ho isa polelong ea ho qetela.(Litlaleho li tla hlaha ho latela tlhoko)

4. e tiisetso ea ho fana ka karabo nakong ea lihora tse 24(hangata ka hora e tšoanang)

5. U ka fumana mefuta e meng ea li-stock, ho tsamaisoa ha leloala ka ho fokotsa nako ea tlhahiso.

6. Re inehetse ka ho feletseng ho bareki ba rona. Haeba ho ke ke ha khoneha ho finyella litlhoko tsa hau ka mor'a ho hlahloba likhetho tsohle, re ke ke ra u khelosa ka ho etsa litšepiso tsa bohata tse tla theha likamano tse ntle tsa bareki.

| Netefatso ea Boleng ea SAKY STEEL (ho kenyeletsoa tse senyang le tse sa senyeheng) |

1. Teko ea Visual Dimension

2. Tlhahlobo ea mochine joalo ka tensile, Elongation le phokotso ea sebaka.

3. Teko e kholo

4. Tlhahlobo ea tlhahlobo ea lik'hemik'hale

5. Teko ea boima

6. Teko ea tšireletso ea likoti

7. Flaring Testing

8. Teko ea Jet ea Metsi

9. Penetrant Test

10. Tlhahlobo ea X-ray

11. Intergranular Corrosion Testing

12. Tlhahlobo ea phello

13. Metallography Teko ea Teko

| SAKY TŠEPILE Sephutheloana: |

1. Ho paka ho bohlokoa haholo-holo tabeng ea thepa ea machaba eo thepa e fetang ka litsela tse fapa-fapaneng ho fihla moo e eang teng, kahoo re amehile haholo ka ho paka.

2. Saky Steel e paka thepa ea rona ka mekhoa e mengata ho latela lihlahisoa. Re paka lihlahisoa tsa rona ka mekhoa e mengata, joalo ka,

Lisebelisoa:

1. Likarolo tsa likoloi, Lisebelisoa tsa bongaka

2. Mocheso oa Mocheso, indasteri ea Lijo

3. Temo,Motlakase, Lik'hemik'hale

4. Lik'hemik'hale tsa mashala; Ho hlahlojoa ha oli le khase

5. Ho hloekisa peterole, Khase ea Tlhaho; Lisebelisoa