304 Kuʻi ʻia ʻana o ka paipu kuhili ʻole

ʻO ka wehewehe pōkole:

| Nā kikoʻī okuhiliʻole kila welded paipu: |

ʻO ka nui o nā paipu a me nā paipu ʻole:1 / 8″ NB – 24″ NB

Nā kikoʻī:ASTM A/ASME A249, A268, A269, A270, A312, A790

Papa:304, 304L, 316, 316L, 321, 409L

Ka lōʻihi:5.8M,6M & Koi ʻia ka lōʻihi

Anawaena waho:6.00 mm OD a hiki i 1500 mm OD

mānoanoa :0.3mm – 20mm,

Hōʻike:SCH 5, SCH10, SCH 40, SCH 80, SCH 80S

Hoʻopau ʻili:Mill Finish, Polishing (180 #, 180 # hairline, 240 # hairline, 400 #,600 #), Mirror etc

Nā ʻano:Weled, EFW, ERW

ʻAno:Poʻai, ʻAha, ʻAhaʻahaʻa

Hoʻopau :Wela Plain, Wela Beveled

| ʻO ke kila kila 304/304L nā paipu huila like ʻole: |

| KANAWAI | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 304 | 1.4301 | S30400 | SUS 304 | 304S31 | 08Х18Н10 | Z7CN18-09 | X5CrNi18-10 |

| SS 304L | 1.4306 / 1.4307 | S30403 | SUS 304L | 3304S11 | 03Х18Н11 | Z3CN18-10 | X2CrNi18-9 / X2CrNi19-11 |

| SS 304 / 304L Welded Pipes Chemical Composition and Mechanical properties: |

| Papa | C | Mn | Si | P | S | Cr | Ni |

| SS 304 | 0.08 ka nui | 2 max | 0.75 ka nui | 0.045 ka nui | 0.030 ka nui | 18 – 20 | 8 – 11 |

| SS 304L | 0.035 ka nui | 2 max | 1.0 ka nui | 0.045 ka nui | 0.03 ka nui | 18 – 20 | 8 – 13 |

| ʻO ka mānoanoa | Lae hehee | Ikaika U'i | Ka ikaika o ka hua (0.2%offset) | ʻO ka lōʻihi |

| 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

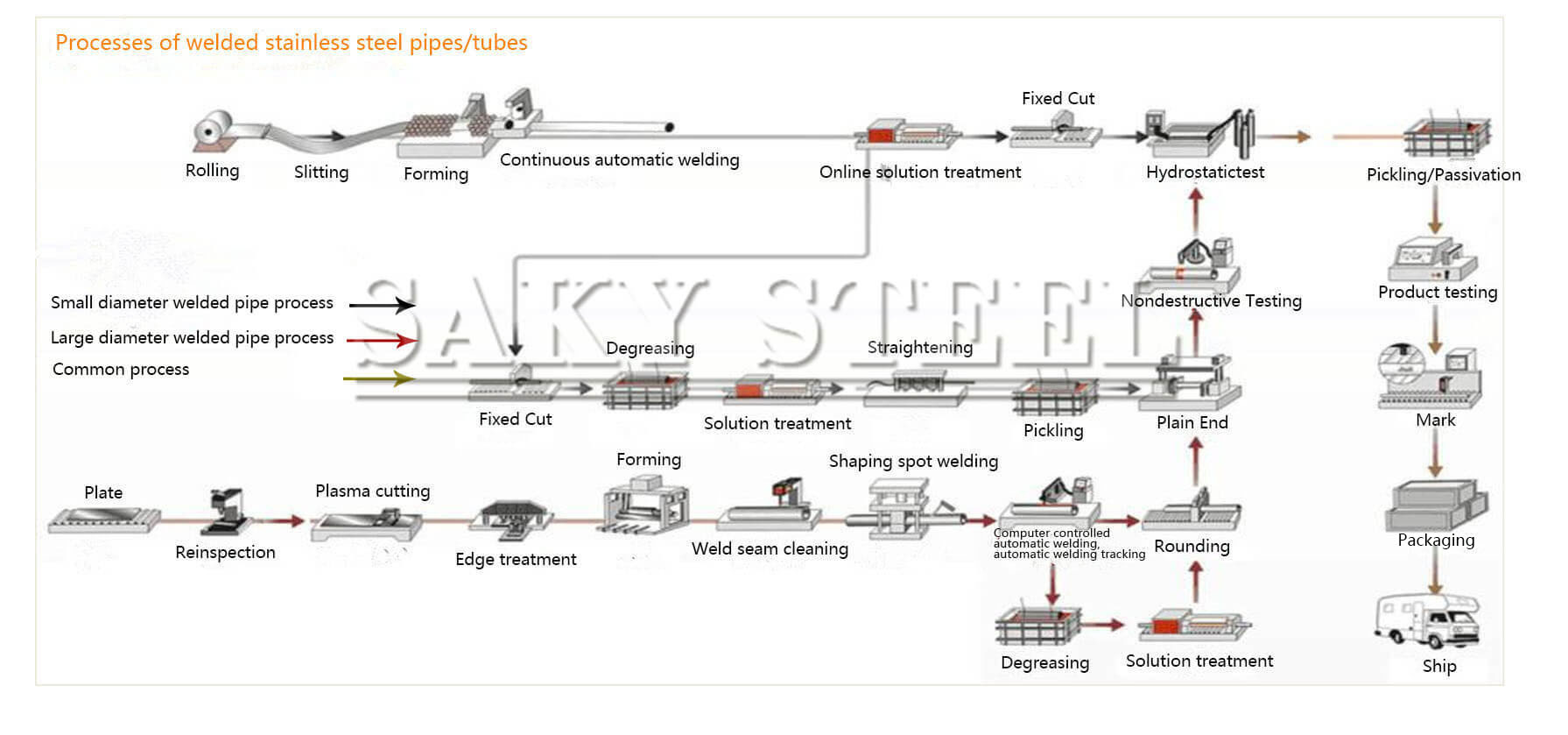

| Nā kaʻina hana o nā paipu / paipu kila kuhili ʻole: |

| Nā koho hoʻopau ʻili: |

Hāʻawi mākou i ʻelua ʻano o ka brushing kuhikuhi e hoʻokō i nā pono hoʻonaninani a me nā pono hana:

Lāʻi lauoho Pololei (Longitudinal Brushing):

Holo ka palaoa ma ka lōʻihi o ka paipu, e hana ana i kahi hopena ʻike maʻemaʻe a hoʻomau. He kūpono no ka hoʻonani ʻana i ka elevator, nā lima lima kūkulu hale, nā paipu lako, a me nā noi kiʻekiʻe.

Lāʻau lauoho keʻa

Hoʻopuni ka palaoa i ka pōʻai o ka paipu, e hāʻawi ana i kahi hiʻohiʻona kūʻokoʻa no nā mea hoʻopili hope, nā ʻāpana hana, a me nā hoʻolālā hoʻonaninani maʻamau.

|  |

| Lāʻau lauoho keʻa | Lāʻi lauoho Pololei |

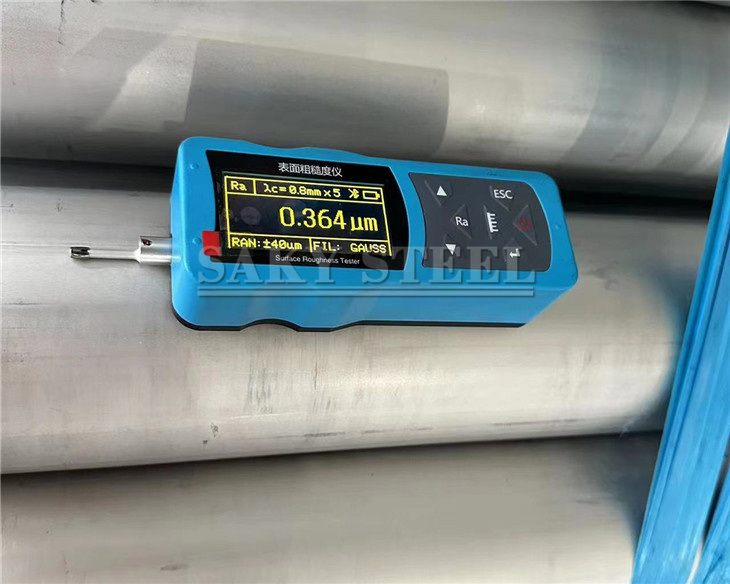

| 304 Hoʻāʻo ʻia ʻo Tubing Weld Roughness |

Ma SAKY STEEL, hana mākou i ka hoʻāʻo ʻana i ka ʻinoʻino ma luna o nā paipu kila kila e hōʻoia i ka ʻili maʻemaʻe a paʻa i kūpono i nā kūlana honua. ʻO ka ʻawaʻawa paipu ke kumu nui e pili ana i ka hoʻoheheʻe ʻana i ka corrosion resistance a me ka hana holoʻokoʻa i nā noi koʻikoʻi.

Hoʻohana mākou i nā mea hana pololei no ke ana ʻana i nā waiwai ʻinoʻino o ka ʻili e hōʻoia ana i nā paipu āpau e hoʻokō i nā koi o ka mea kūʻai aku no ka maʻalahi a me ka pau ʻana. He kūpono ko mākou paipu no ka hoʻoponopono ʻana i nā meaʻai kemika a me nā ʻoihana hoʻolālā kahi e pono ai ka maikaʻi o ka ʻili.

|  |

| 304 Kuhili ʻole Welded Tube Surface Ho'āʻo |

He mea koʻikoʻi ka hoʻopau ʻana o ka ʻili o nā paipu kila kila no ka hana a me ke ʻano. Ma SAKY STEEL ke hoʻomalu pono nei mākou i ka maikaʻi o ka ʻili ma o nā kaʻina hoʻokele holomua. Hōʻike ke kiʻi i ka hoʻohālikelike maopopo ʻana ma waena o nā paipu ʻili maikaʻi ʻole me nā hemahema ʻike ʻia a me kā mākou paipu ʻili maikaʻi me ka hoʻopau ʻana a me ka ʻano like.

ʻO kā mākou mau paipu kila kila ʻole mai nā māwae lua a me nā hōʻailona wili e hōʻoiaʻiʻo ana i ke kūpaʻa maikaʻi a me ka hilinaʻi. Hoʻohana nui ʻia kēia mau paipu i loko o ke kai kemika a me nā noi hoʻolālā kahi e pono ai ka pono o ka ʻili.

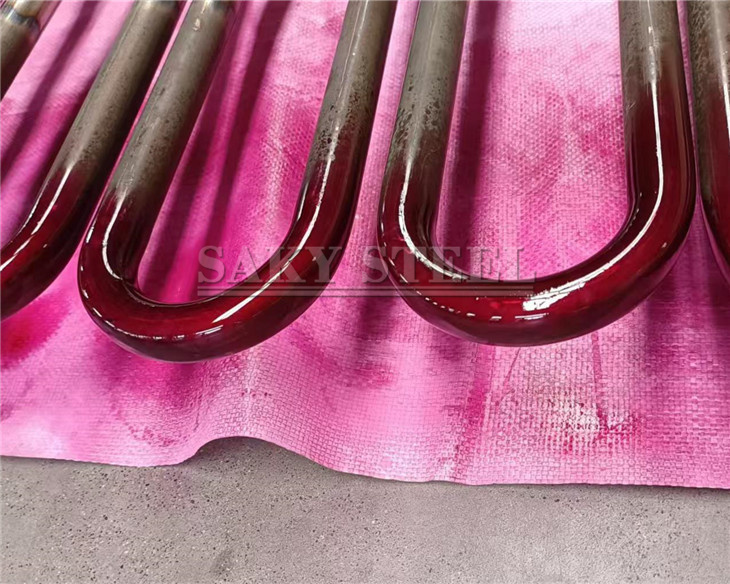

| 304 Kuhiliahi Welded Paipu PT Ho'āʻo |

Hana ʻo SAKY STEEL i ka hoʻāʻo penetrant PT ma nā paipu kila kila a me nā ʻāpana ma ke ʻano o kā mākou kaʻina hoʻomalu maikaʻi. ʻO ka PT he hana hoʻāʻo ʻole luku i hoʻohana ʻia no ka ʻike ʻana i nā hemahema o ka ʻili e like me ka porosity māwae a me nā inclusions ʻike ʻole ʻia e ka maka ʻōlohelohe.

Hoʻopili kā mākou mau mea nānā i hoʻomaʻamaʻa ʻia i nā mea penetrant a me nā mea hoʻomohala kiʻekiʻe e hōʻoia i nā hopena pololei a hilinaʻi. ʻO nā kaʻina PT āpau e hahai i nā kūlana honua a me nā kikoʻī o ka mea kūʻai aku e hōʻoiaʻiʻo ana i ka palekana a me ka hana.

|  |

| Weld Seam Inspection of 304 Stainless Steel Welded Paipu |

ʻO ka nānā ʻana i nā wili wili a pau i ka maikaʻi a me nā kūlana palekana. Hoʻopili ke kaʻina hana i ka ʻike ʻana i ka ʻili a me nā hemahema o loko e like me nā māwae, porosity, slag inclusions, nele o ka hui ʻana, a me ke komo ʻole ʻana. ʻO nā ʻano hana maʻamau ka nānā ʻana i ka ʻike, ka hoʻāʻo ʻana i ka dye penetrant, ka hoʻāʻo kani ultrasonic, a me ka hoʻāʻo radiographic. Koho ʻia kēlā me kēia ʻano ma muli o ka mea paipu, ka mānoanoa o ka paia, a me nā kūlana lawelawe. Hana ʻia nā nānā āpau e like me nā kūlana honua e like me ASME, ASTM, a me ISO e hōʻoiaʻiʻo i ka pono a me ka hana o nā paipu welded.

|  |

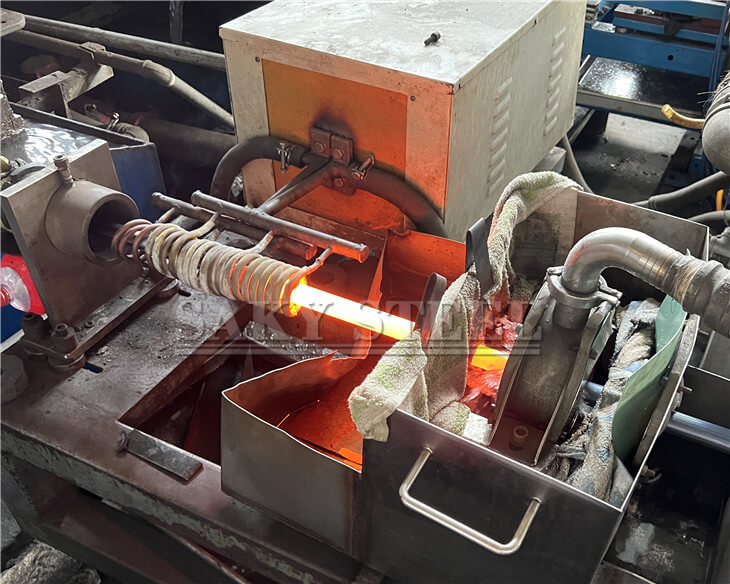

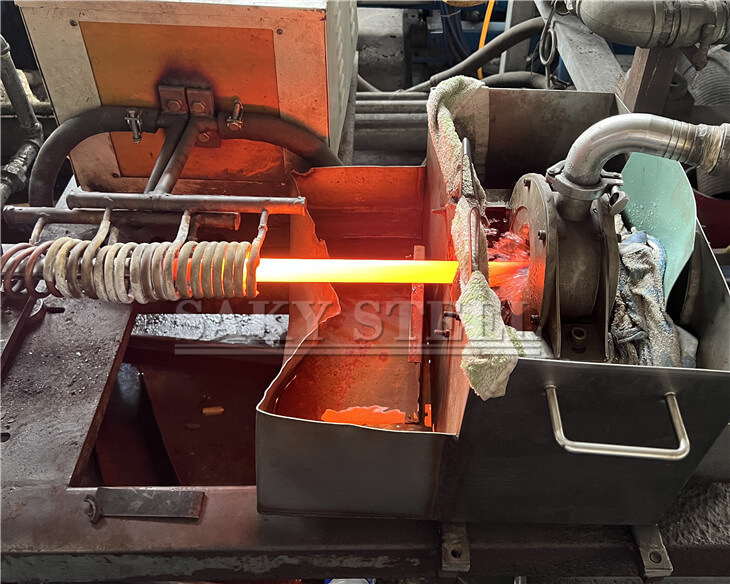

| ʻO ka hoʻonā ʻana i loko o ka laina e hoʻopili ana i ka paipu kuhili ʻole |

In-line solution annealing o ka paipu kila kila he kaʻina hana mālama wela i hoʻohana ʻia i ka wā o ka hana ʻana e hoʻokō i kahi microstructure austenitic like ʻole a hoʻonui i ka pale ʻana i ka corrosion. Hoʻomaʻamaʻa ʻia ka paipu i ka wela annealing solution i ʻōlelo ʻia, maʻamau ma waena o 1000°C a me 1150°C, a laila hoʻomaʻalili wikiwiki, me ka hoʻohana pinepine ʻana i ka wai quenching a i ʻole ka hoʻoluʻu ʻana i ka ea. Hoʻopau kēia kaʻina hana i ka carbide precipitates a pale i ka corrosion intergranular, e hōʻoia ana i nā waiwai mechanical a me ka maikaʻi o ka ʻili e kūpono i nā kūlana honua. Hoʻomaikaʻi ka hoʻopili ʻana i ka hopena in-line i ka hana hana ʻoiai e mālama mau ana i ka hana huahana.

|  |

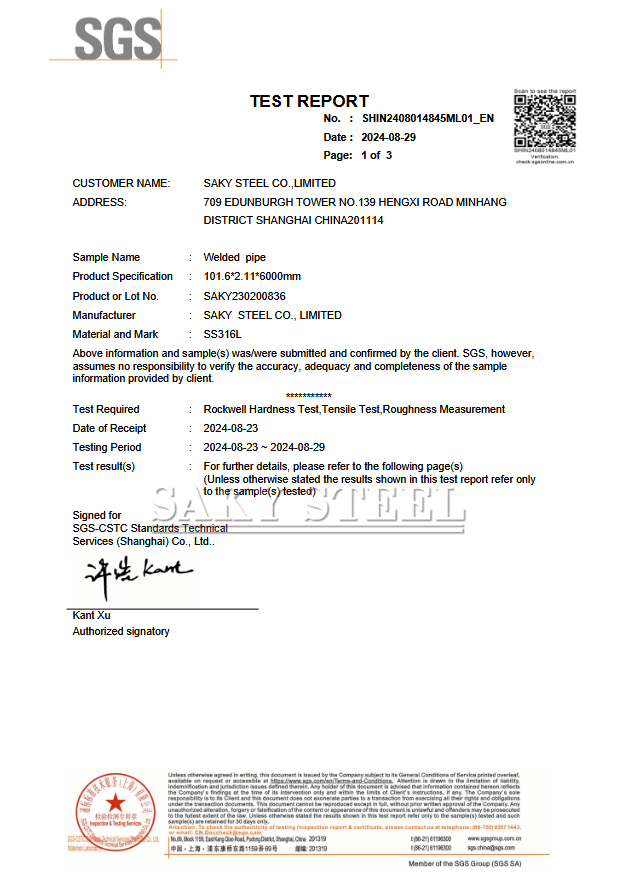

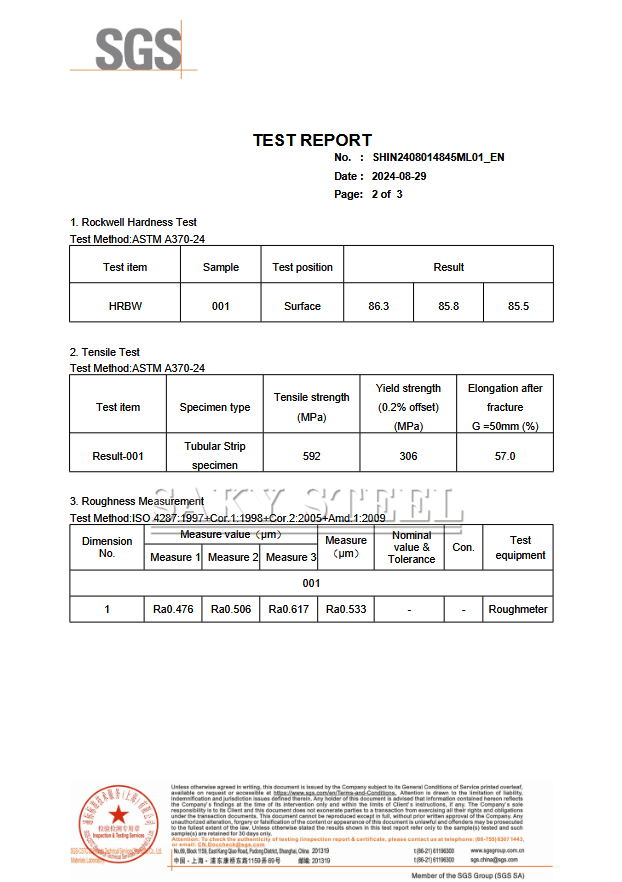

| Hoike hoao paipu welo |

Ua hoʻāʻo ʻia nā waiwai mechanical o ka huahana e like me ka ASTM A370 Standard Test Methods and Definitions for Mechanical Testing of Steel Products. ʻO nā hopena hōʻike a pau, me ka ikaika tensile, ka ikaika hua, elongation, a me ka paʻakikī, e hoʻokō i nā koi i kuhikuhi ʻia a ua kākau ʻia ma ke ʻano o kēia palapala hōʻoia e hōʻoia i ka conformity i nā kūlana kūpono a me nā kikoʻī o ka mea kūʻai aku.

|  |  |

| No ke aha e koho ai iā mākou |

1. Hiki iā ʻoe ke loaʻa ka mea kūpono e like me kāu koi ma ka liʻiliʻi loa o ke kumu kūʻai.

2. Hāʻawi pū mākou i nā Reworks, FOB, CFR, CIF, a me nā kumukūʻai hoʻopuka puka. Manaʻo mākou iā ʻoe e hana i ka hana no ka hoʻouna ʻana e ʻoi aku ka waiwai.

3. ʻO nā mea a mākou e hāʻawi nei ua hiki ke hōʻoia ʻia, mai ka palapala hōʻike maka a hiki i ka ʻōlelo kikoʻī hope loa. (E hōʻike ʻia nā hōʻike ma ke koi)

4. e hōʻoiaʻiʻo e hāʻawi i ka pane i loko o 24 hola (maʻamau i ka hola hoʻokahi)

5. Hiki iā ʻoe ke kiʻi i nā mea kūʻai ʻokoʻa, nā hāʻawi wili me ka hōʻemi ʻana i ka manawa hana.

6. Hoʻolaʻa piha mākou i kā mākou mea kūʻai. Inā ʻaʻole hiki ke hoʻokō i kāu mau koi ma hope o ka nānā ʻana i nā koho āpau, ʻaʻole mākou e alakaʻi hewa iā ʻoe ma ka hana ʻana i nā ʻōlelo hoʻohiki wahaheʻe e hoʻokumu ai i nā pilina mea kūʻai aku.

| ʻO SAKY STEEL'S Quality Assurance (me nā mea hoʻopau a me ka hoʻopau ʻole) |

1. Ho'āʻo ʻana i ke ana ʻike

2. Mechanical nānā 'ana e like me tensile, Elongation a me ka ho'ēmi 'āpana.

3. Ka ho'āʻo nui

4. Ka nānā 'ana i ka ho'ā'o kemika

5. Hoao paakiki

6. Ho'āʻo pale lua

7. Ho'āʻo Flaring

8. Hoao Wai-Jet

9. Hoao Penetrant

10. X-ray hoao

11. Intergranular Corrosion Hoao

12. Ka nānā 'ana i ka hopena

13. Ho'āʻo hoʻokolohua Metallography

| SAKY STEEL'S Packaging: |

1. He mea koʻikoʻi ka hoʻopaʻa ʻana ma ka hihia o ka hoʻouna ʻana i ka honua kahi e hele ai ka lawe ʻana ma nā ala like ʻole e hiki ai i ka hopena hope loa, no laila ke kau nei mākou i ka manaʻo nui e pili ana i ka ʻeke.

2. Hoʻopili ʻo Saky Steel i kā mākou waiwai ma nā ʻano he nui e pili ana i nā huahana. Hoʻopili mākou i kā mākou huahana ma nā ʻano he nui, e like me,

Nā noi:

1. Nā ʻāpana kaʻa, Lapaʻau lapaʻau

2. Heat Exchanger, ʻOihana meaʻai

3. Mahiai, Uila, Kemika

4. Kemika lanahu; ʻImi ʻaila a me ke kinoea

5. Hoomaemae aila, Kinoea maoli; Mea hana